Moster185 Plus

TRACKING A NEW WAY IN THE SKY

Scroll down

TRACKING A NEW WAY IN THE SKY

MY25

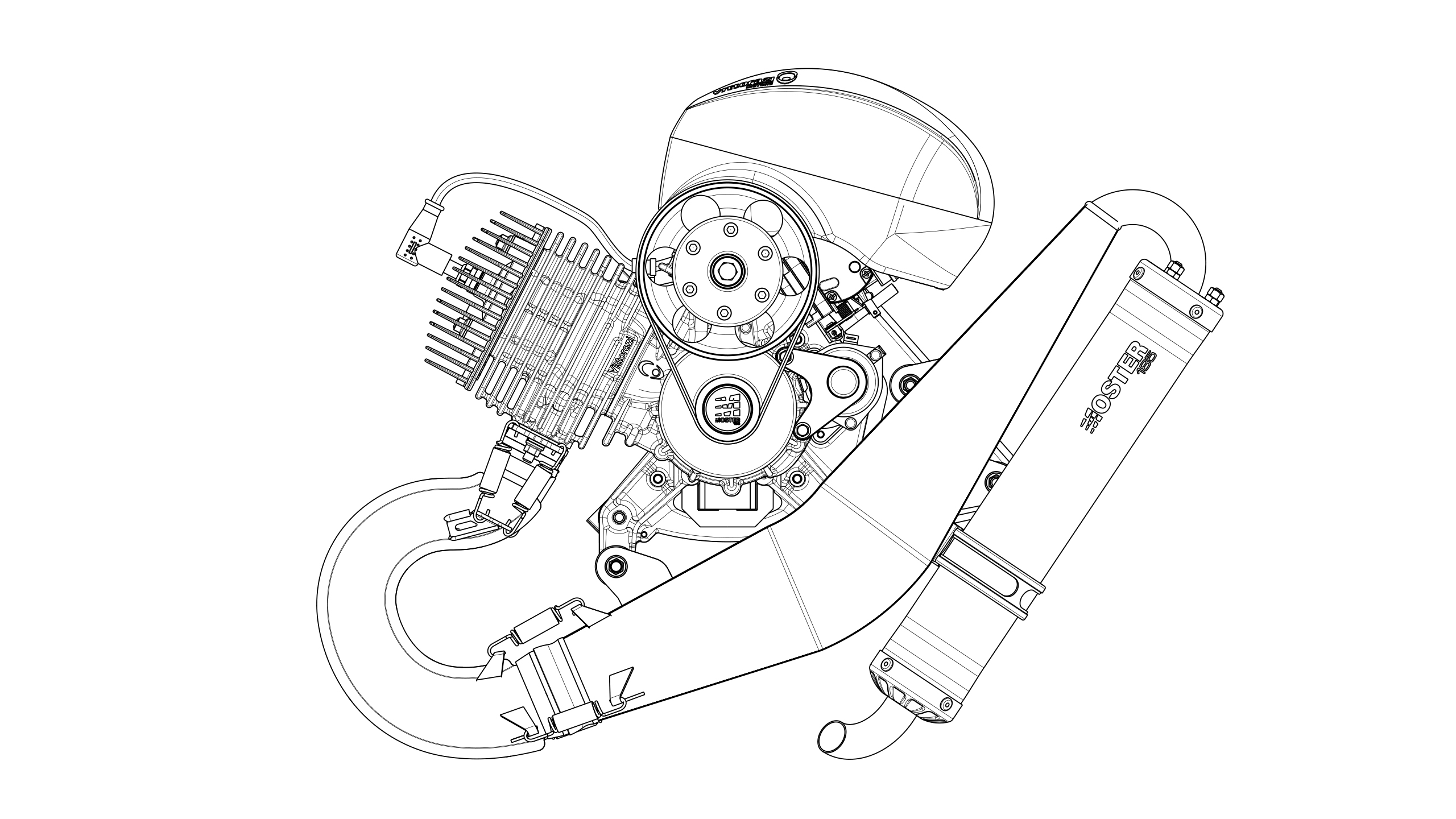

The Moster185 is a sporty and highly versatile engine. Whether you are a Cross-Country enthusiast or a pilot who loves competitions, this engine is your perfect and reliable flying companion. With extraordinary performance, this engine has conquered the skies over the years, quickly becoming the most desired and best-selling engine in the world of paramotoring. The Moster185, an engine for great achievements, has been further enhanced in its MY25 version.

A STORY OF EXCELLENCE

For over a decade, the Moster185 has embodied the core values of Vittorazi. Each release has strengthened its reputation as an engine of exceptional performance, outstanding durability, and ease of use, delivering an unparalleled flying experience. It is the most widely flown engine, backed by extensive availability of spare parts and global support.

Scroll with your finger on the image

for 360° engine rotation

Show more

High level performance

With smooth thrust reaching up to 75 kg with a 125 cm propeller and 78 kg with a 130 cm propeller, the Moster185 elevates the concept of power-to-weight ratio, solidifying its status as a benchmark for excellence in paramotor engines. Every detail is designed to maximize performance and quality, while the standard provision for EGT and CHT probes ensures constant engine monitoring.

Cycle

2 strokes

Displacement

184,7 cc

Power

25 HP at 7.800 RPM

Air intake

Airbox silencer - Diaphragm carburettor - Reed valve intake

Cooling system

Air cooled, flow extraction from propeller

Show more

Combustion

Vittorazi's continuous research has resulted in optimized airflow through a study of the transfers and exhaust. The crankshaft, balanced with precision, minimizes vibration. The MY25 cylinder head is designed with the standard provision for a dedicated CHT (cylinder head temperature) probe, equipped with robust crimping and heat-protective sheathing, fixed in a strategic position on the new cylinder head and designed to withstand vibration and high temperatures. The new MY25 conveyor features a new updated fastening system with screws, anti-loosening washers, spacers for stable connections, and reinforced anti-vibration mounts.

Airbox

The new airbox of the Moster185 MY25 features optimized geometries to enhance the component's strength and durability, improving stress distribution. These updates ensure greater longevity and reliability, reduce vibrations, and deliver consistent performance. Additionally, the design has been updated with a new texture, combining functionality and elegance. In addition, the design of the components incorporated an analysis of changes in material stiffness as a function of temperature, ensuring that the airbox maintains optimal and consistent performance in all weather conditions.

Electric Starter

The electric starter system of the Moster185 is designed to provide unparalleled ease of ignition, combining compact technology with intuitive functionality. With the use of a single button, starting the engine becomes a simple and immediate operation, minimizing effort both on the ground and in the air. This system offers complete management freedom, ensuring maximum comfort in any situation.

Exhaust

The Moster185 MY25 introduces a second self-lubricating bronze bushing, enhancing mobility, and significantly reducing stress. In addition, the new MY25 manifold introduces standard provision for the EGT (Exhaust Gas Temperature) probe, made with industrial-grade specifications and “in-house” welding processes. The probe, equipped with robust crimping and heat-protective sheathing, ensures accurate readings and optimal control. This improves motor longevity with control that reduces wear and optimizes operating conditions. The exhaust system simplifies maintenance operations thanks to added holes on the flange. Finally, the silencer stands out with more stable mountings, a racing-inspired aesthetic design, and unique customizations.

Combustion

Vittorazi's continuous research has resulted in optimized airflow through a study of the transfers and exhaust. The crankshaft, balanced with precision, minimizes vibration. The MY25 cylinder head is designed with the standard provision for a dedicated CHT (cylinder head temperature) probe, equipped with robust crimping and heat-protective sheathing, fixed in a strategic position on the new cylinder head and designed to withstand vibration and high temperatures. The new MY25 conveyor features a new updated fastening system with screws, anti-loosening washers, spacers for stable connections, and reinforced anti-vibration mounts.

Airbox

The new airbox of the Moster185 MY25 features optimized geometries to enhance the component's strength and durability, improving stress distribution. These updates ensure greater longevity and reliability, reduce vibrations, and deliver consistent performance. Additionally, the design has been updated with a new texture, combining functionality and elegance. In addition, the design of the components incorporated an analysis of changes in material stiffness as a function of temperature, ensuring that the airbox maintains optimal and consistent performance in all weather conditions.

Electric Starter

The electric starter system of the Moster185 is designed to provide unparalleled ease of ignition, combining compact technology with intuitive functionality. With the use of a single button, starting the engine becomes a simple and immediate operation, minimizing effort both on the ground and in the air. This system offers complete management freedom, ensuring maximum comfort in any situation.

Exhaust

The Moster185 MY25 introduces a second self-lubricating bronze bushing, enhancing mobility, and significantly reducing stress. In addition, the new MY25 manifold introduces standard provision for the EGT (Exhaust Gas Temperature) probe, made with industrial-grade specifications and “in-house” welding processes. The probe, equipped with robust crimping and heat-protective sheathing, ensures accurate readings and optimal control. This improves motor longevity with control that reduces wear and optimizes operating conditions. The exhaust system simplifies maintenance operations thanks to added holes on the flange. Finally, the silencer stands out with more stable mountings, a racing-inspired aesthetic design, and unique customizations.

VITTORAZI MOTORS 250CC

(POR Marche FESR 2014-2020 Asse 1 - OS 1 - Azione 1.2)

Il progetto prevede, a partire da risultati di ricerca già acquisiti, l'ingegnerizzazione e l'industrializzazione di un nuovo prodotto..

Il progetto ha tra gli obiettivi: l'ingegnerizzazione e prototipazione esecutiva del nuovo motore, il miglioramento delle caratteristiche prestazionali e tecniche del prodotto, l'industrializzazione del nuovo motore, la promozione del prodotto innovativo e sviluppo della fase di commercializzazione per il nuovo mercato.

Ingegnerizzare, industrializzare e produrre il nuovo motore da proporre a un nuovo settore di clientela, acquisendo una fetta di mercato importante per lo sviluppo dell'impresa.

Investimento totale: 687.291,60 euro | Finanziamento pubblico: 337.675,80