object(WP_Post)#4972 (24) {

["ID"]=>

int(3968)

["post_author"]=>

string(1) "2"

["post_date"]=>

string(19) "2020-12-07 10:05:47"

["post_date_gmt"]=>

string(19) "2020-12-07 09:05:47"

["post_content"]=>

string(2943) "

Moster 185 propellers | Lower Vibrations

The study carried out by the Vittorazi and Helix team led to the creation of a product that allow the greatest damping of vibrations in combination with the Moster 185 engine. Complex work has therefore been done to measure the vibrations on different propellers to reach the minimum level perceived by the pilot, as well as avoiding resonance frequencies across the entire engine RPM range. This allowed to optimize the vibration levels of the propellers, working incrementally and iteratively on the stiffeners obtained with different layers and positions of the carbon fibre inside the propeller.

Moster 185 propellers | More safety during take-off

The design of the propeller has been studied in every detail, also in this case to optimize performance and ensure exceptional comfort. The curvature of the propeller has been studied and designed to move the propeller tip away from the frame, offering the pilot greater safety during take-off.

This curvature ensures optimised thrust during the flight, optimising energy transfer in turbulent airflow.

Moster 185 propellers | All the test carried out

The propellers passed the test bench tests to ensure proper operation, they were also repeatedly tested in flight, comparing them with other prototypes. In addition, at the end of the development, important long endurance tests were carried out lasting over 200 hours at maximum power and under extreme conditions. They ensured that the combination was safe, reliable and of the highest quality. This is the reason why the Vittorazi engines are guaranteed only with approved propellers.

Moster 185 propellers | The logo, a guarantee of authenticity

We have also included an engraved logo in the propeller, so as to avoid counterfeiting. It is a warranty trademark for the customer: the approved propellers are the original ones coming from the Vittorazi sales network and of high quality standard.

"

["post_title"]=>

string(41) "MOSTER 185 PROPELLERS: COMFORT & SECURITY"

["post_excerpt"]=>

string(0) ""

["post_status"]=>

string(7) "publish"

["comment_status"]=>

string(6) "closed"

["ping_status"]=>

string(6) "closed"

["post_password"]=>

string(0) ""

["post_name"]=>

string(38) "moster-185-propellers-comfort-security"

["to_ping"]=>

string(0) ""

["pinged"]=>

string(0) ""

["post_modified"]=>

string(19) "2021-10-06 16:10:28"

["post_modified_gmt"]=>

string(19) "2021-10-06 14:10:28"

["post_content_filtered"]=>

string(0) ""

["post_parent"]=>

int(0)

["guid"]=>

string(55) "http://www.vittorazi.com/?post_type=notizia&p=3968"

["menu_order"]=>

int(148)

["post_type"]=>

string(7) "notizia"

["post_mime_type"]=>

string(0) ""

["comment_count"]=>

string(1) "0"

["filter"]=>

string(3) "raw"

}

07/12/2020

MOSTER 185 PROPELLERS: COMFORT & SECURITY

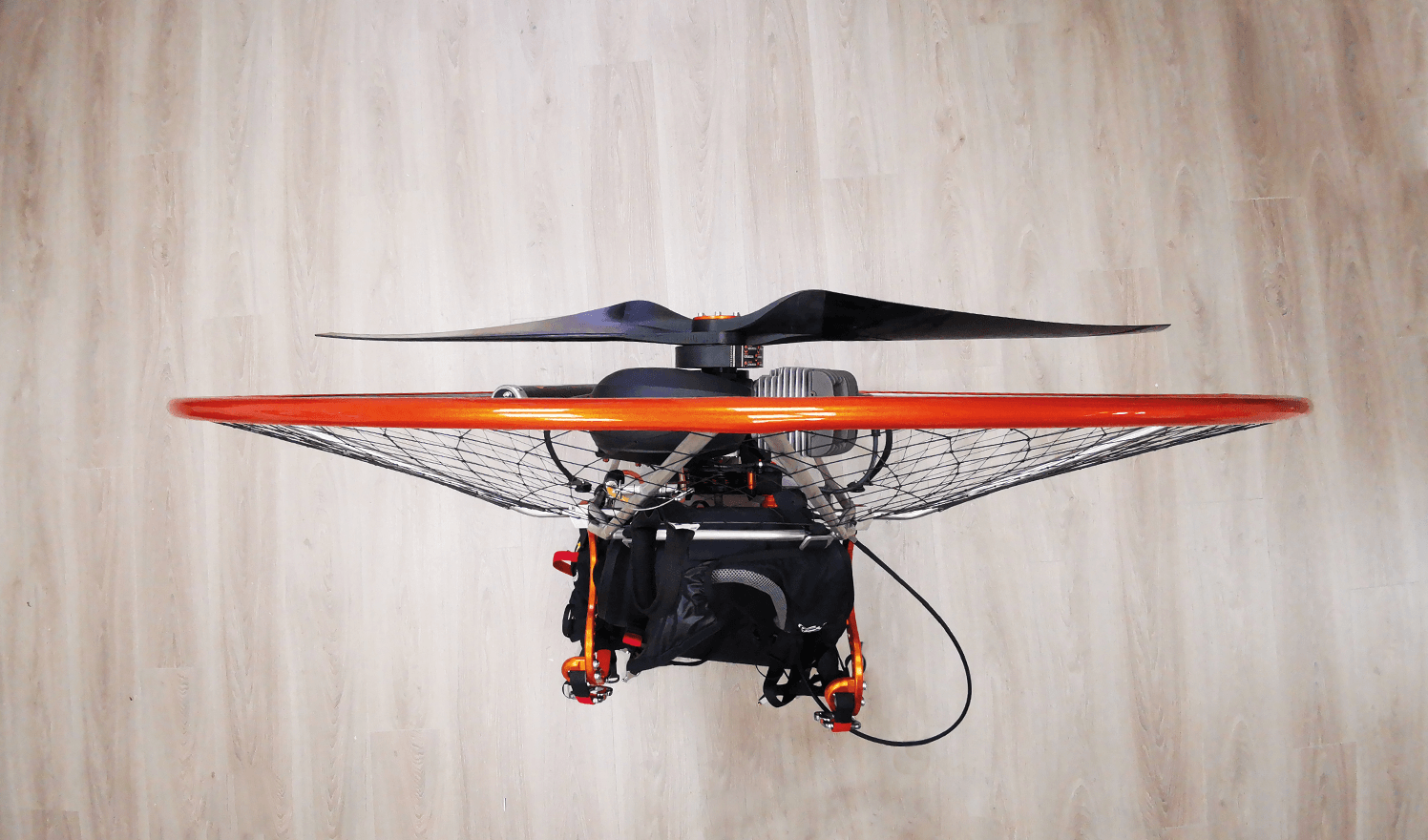

Moster 185 propellers | Lower Vibrations

The study carried out by the Vittorazi and Helix team led to the creation of a product that allow the greatest damping of vibrations in combination with the Moster 185 engine. Complex work has therefore been done to measure the vibrations on different propellers to reach the minimum level perceived by the pilot, as well as avoiding resonance frequencies across the entire engine RPM range. This allowed to optimize the vibration levels of the propellers, working incrementally and iteratively on the stiffeners obtained with different layers and positions of the carbon fibre inside the propeller.

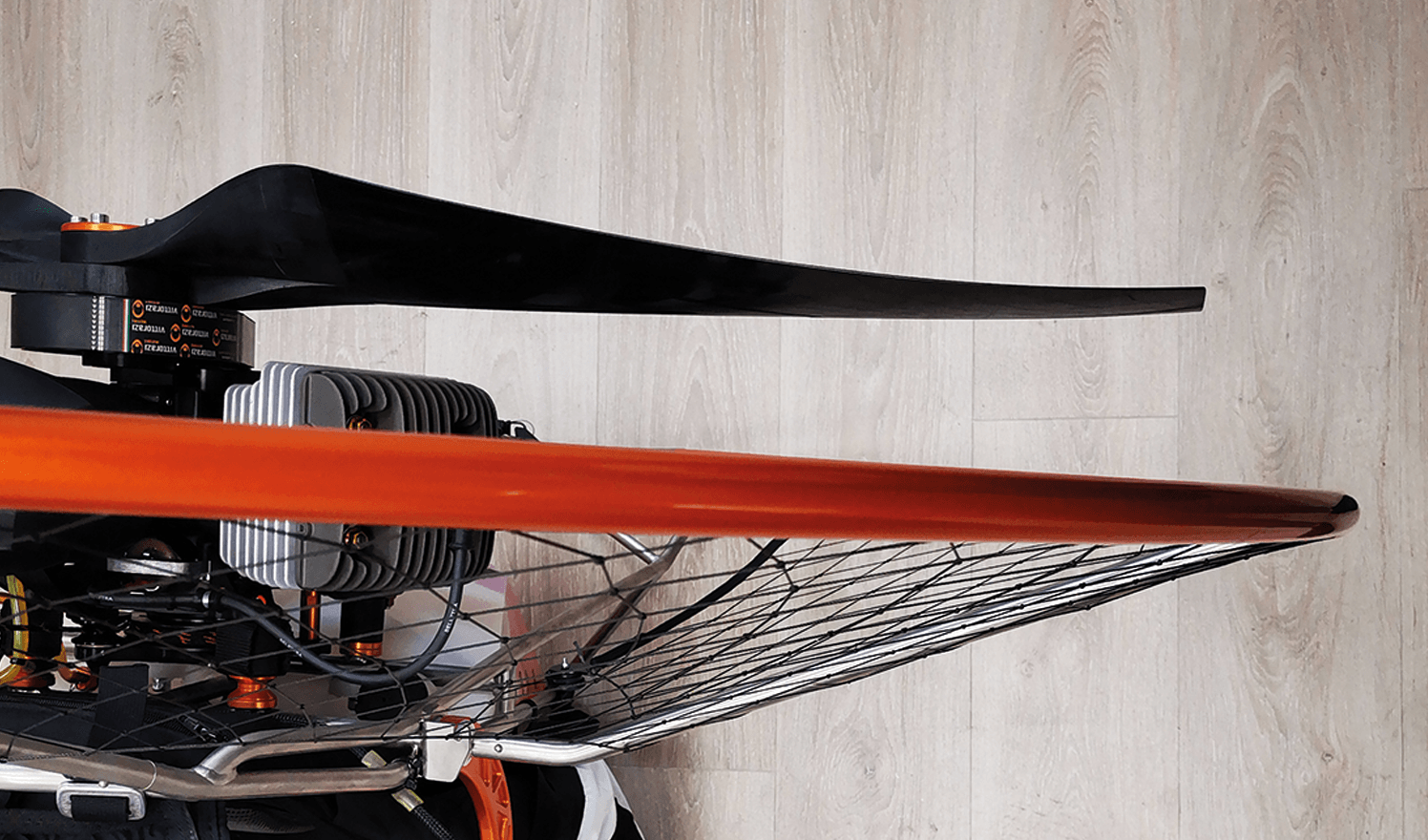

Moster 185 propellers | More safety during take-off

The design of the propeller has been studied in every detail, also in this case to optimize performance and ensure exceptional comfort. The curvature of the propeller has been studied and designed to move the propeller tip away from the frame, offering the pilot greater safety during take-off.

This curvature ensures optimised thrust during the flight, optimising energy transfer in turbulent airflow.

Moster 185 propellers | All the test carried out

The propellers passed the test bench tests to ensure proper operation, they were also repeatedly tested in flight, comparing them with other prototypes. In addition, at the end of the development, important long endurance tests were carried out lasting over 200 hours at maximum power and under extreme conditions. They ensured that the combination was safe, reliable and of the highest quality. This is the reason why the Vittorazi engines are guaranteed only with approved propellers.

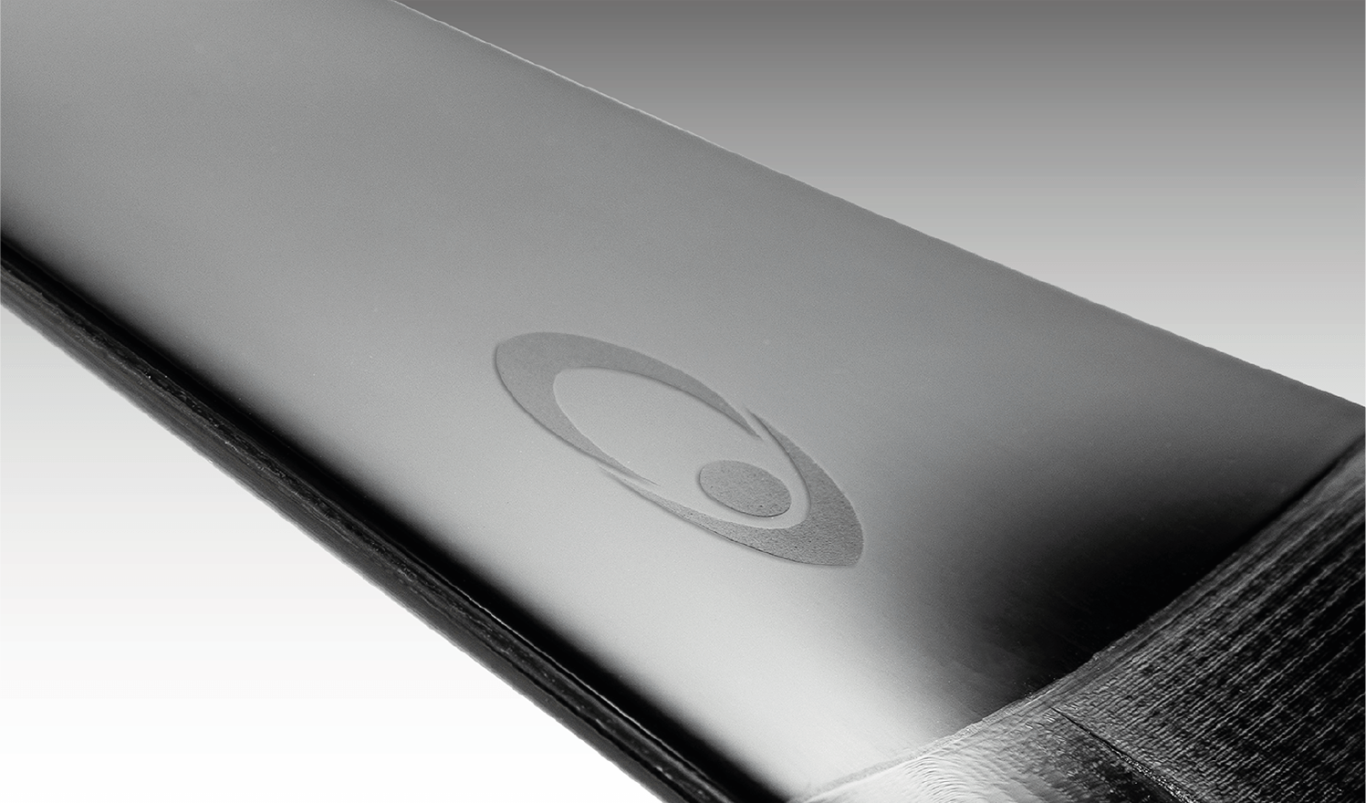

Moster 185 propellers | The logo, a guarantee of authenticity

We have also included an engraved logo in the propeller, so as to avoid counterfeiting. It is a warranty trademark for the customer: the approved propellers are the original ones coming from the Vittorazi sales network and of high quality standard.