10/03/2016

NEW AIR CONVEYOR FOR MOSTER 185

In order to improve constantly their products, Vittorazi Motors have developed a new Air shroud for Moster185. In the new model, the fixing points are no longer at the head (upper part) of the engine: they are placed on its sides.

Thanks to this new solution, the airflow passes through the fins finding less obstacles and allowing a greater and better heat dissipation. The tests carried out about one year ago confirmed that the temperature values are lower by 5-10% compared to what happens with other conveyors on the market. Installing this new conveyor will prove much easier, and it will make it easier to check head nuts.

Both the conveyor and the fixing kit weight have been significantly reduced (the total weight is only 155 grams unlike the 300 grams of the previous version) without affecting the engine quality and durability.

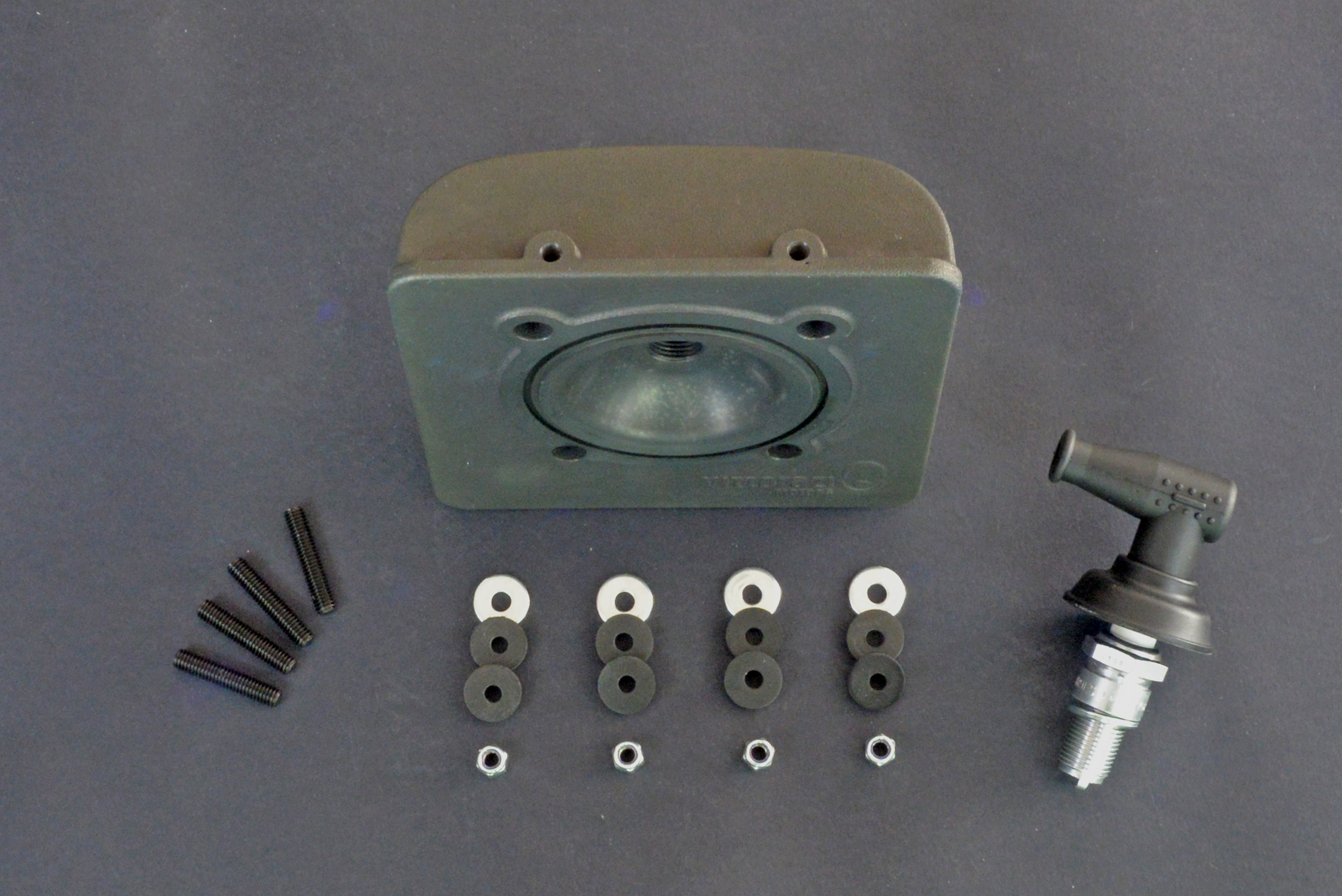

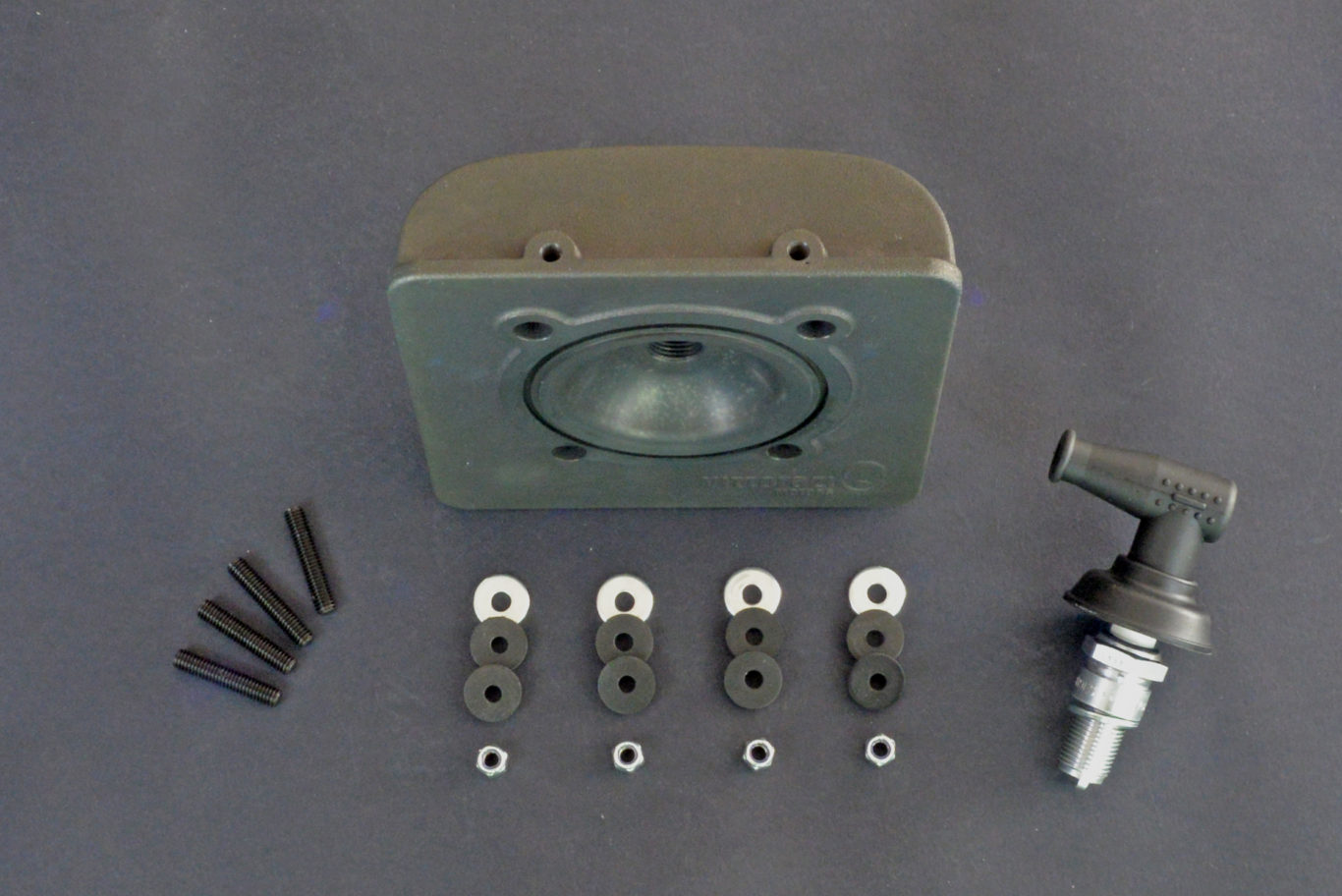

The new Air conveyor for Moster185 will be soon available. It can be mounted only on engines having the 2016 new cylinder head with the fixing holes on the sides (see picture). All the Vittorazi engines, starting from January, will have a new cylinder head, while a kit cylinder head/conveyor will be available at a discount for the engines purchased before 2016.