Moster185 Factory-R

MORE TORQUE FOR YOUR THRILL

Scroll down

MORE TORQUE FOR YOUR THRILL

MY25

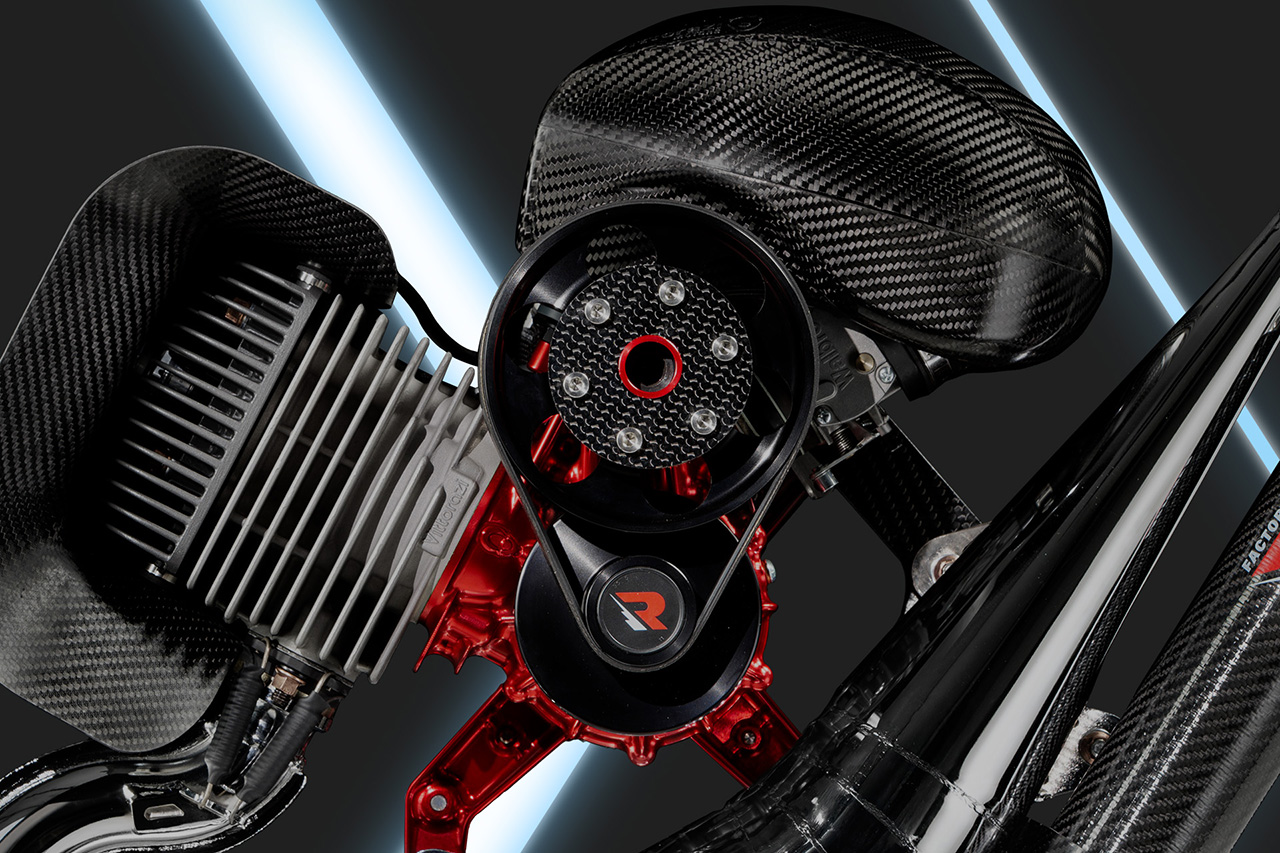

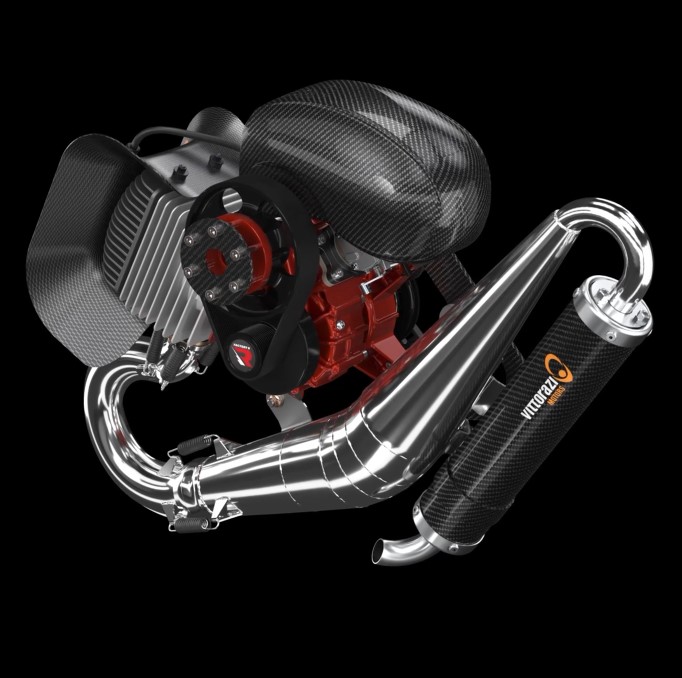

Red like passion, powerful like adrenaline. The Moster185 Factory-R is a brilliant, advanced engine designed to deliver an exciting and unique flying experience. Every component is the result of continuous research aimed at ensuring exceptional performance.

UNIQUE AND DISTINCTIVE

The Moster185 Factory-R is a product of excellence, engineered for peak performance. It boasts a highly distinctive aesthetic: in addition to the chrome-plated exhaust, the engine is available in six vibrant colors—red, orange, gold, silver, green, and blue. Choose the color that best represents you and get ready for an adrenaline-packed experience.

Scroll with your finger on the image

for 360° engine rotation

Show more

LIGHTWEIGHT AND POWERFUL

The Moster185 Factory-R boasts an unmatched power-to-weight ratio in the market. Advanced technology and the use of top-quality materials make it the ideal choice for those who want to fly at their peak, pushing beyond every limit.

Cycle

2 strokes

Displacement

184,7 cc

Power

27 HP at 8.800 RPM

Air intake

Carbon fibre airbox silencer - Diaphragm carburettor - Reed valve intake

Cooling system

Air cooled, flow extraction from propeller, cooling shroud included

Other characteristics

Engine carter case CNC machined from solid aluminium alloy 7075 – Crank rod machined from solid - Carbon fibre airbox – Carbon fibre exhaust bracket - Carbon fibre propeller plate - Carbon fibre cooling shroud - Full kit of titanium screws - Iridium spark plug

Show more

Combustion

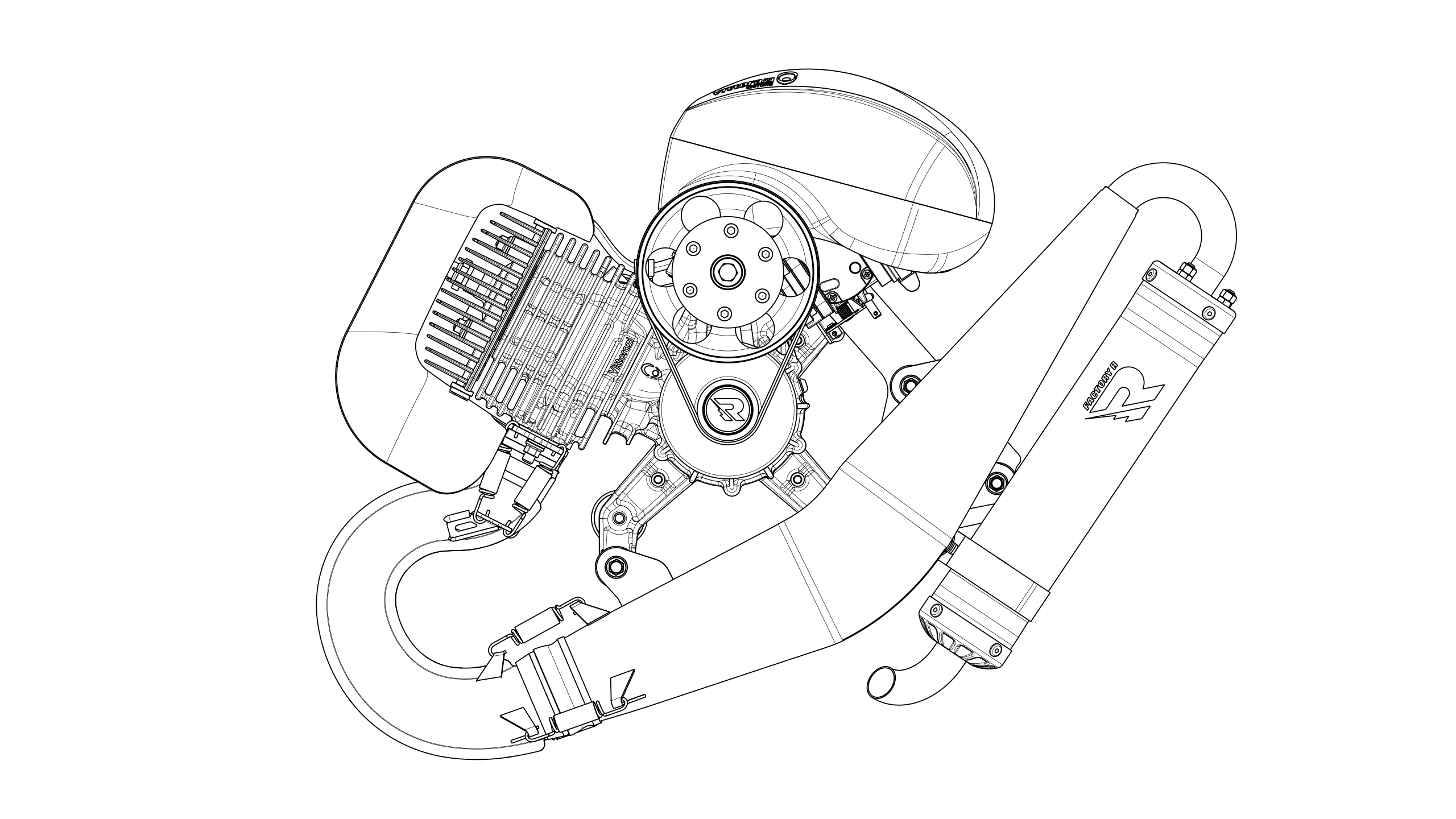

Vittorazi's continuous research has resulted in optimized airflow through a study of the transfers and exhaust. The crankshaft, balanced with precision, minimizes vibration. The MY25 cylinder head is designed with a dedicated CHT (cylinder head temperature) probe, equipped with robust crimping and heat-protective sheathing, fixed in a strategic position on the new cylinder head and designed to withstand vibration and high temperatures. The new MY25 conveyor features a new updated fastening system with screws, anti-loosening washers, spacers for stable connections, and reinforced anti-vibration mounts.

Airbox

The carbon fiber airbox is an engineering marvel: lightweight, high-performing, and efficient. Thanks to fluid dynamics improvements, the system reduces fuel consumption by 10-15% at cruising speeds (5000-6000 rpm) and ensures quick restarts at any speed. The carburation system’s filter, with its dual-layer sponge, effectively separates coarse and fine dust particles, protecting the engine and extending the longevity of its components.

Crankcase

The crankcase of the Moster185 Factory-R MY25, CNC machined from solid in aeronautical Ergal 7075, combines strength, lightness, and customization options. Available in a range of six exclusive colors (red, orange, gold, silver, green, and blue), it allows every pilot to express their unique style.

Exhaust

The Moster185 Factory-R exhaust is fully chromed, an aesthetic detail that gives the engine a unique design. The Moster185 Factory-R MY25 introduces a second self-lubricating bronze bushing, enhancing mobility, and significantly reducing stress. In addition, the new MY25 manifold introduces standard provision for the EGT (Exhaust Gas Temperature) probe, made with industrial-grade specifications and “in-house” welding processes. The probe, equipped with robust crimping and heat-protective sheathing, ensures accurate readings and optimal control. This improves motor longevity with control that reduces wear and optimizes operating conditions. The exhaust simplifies maintenance thanks to the added holes on the flange. Finally, the silencer features more stable fixings, a racing-inspired aesthetic design, and unique customizations.

Combustion

Vittorazi's continuous research has resulted in optimized airflow through a study of the transfers and exhaust. The crankshaft, balanced with precision, minimizes vibration. The MY25 cylinder head is designed with a dedicated CHT (cylinder head temperature) probe, equipped with robust crimping and heat-protective sheathing, fixed in a strategic position on the new cylinder head and designed to withstand vibration and high temperatures. The new MY25 conveyor features a new updated fastening system with screws, anti-loosening washers, spacers for stable connections, and reinforced anti-vibration mounts.

Airbox

The carbon fiber airbox is an engineering marvel: lightweight, high-performing, and efficient. Thanks to fluid dynamics improvements, the system reduces fuel consumption by 10-15% at cruising speeds (5000-6000 rpm) and ensures quick restarts at any speed. The carburation system’s filter, with its dual-layer sponge, effectively separates coarse and fine dust particles, protecting the engine and extending the longevity of its components.

Crankcase

The crankcase of the Moster185 Factory-R MY25, CNC machined from solid in aeronautical Ergal 7075, combines strength, lightness, and customization options. Available in a range of six exclusive colors (red, orange, gold, silver, green, and blue), it allows every pilot to express their unique style.

Exhaust

The Moster185 Factory-R exhaust is fully chromed, an aesthetic detail that gives the engine a unique design. The Moster185 Factory-R MY25 introduces a second self-lubricating bronze bushing, enhancing mobility, and significantly reducing stress. In addition, the new MY25 manifold introduces standard provision for the EGT (Exhaust Gas Temperature) probe, made with industrial-grade specifications and “in-house” welding processes. The probe, equipped with robust crimping and heat-protective sheathing, ensures accurate readings and optimal control. This improves motor longevity with control that reduces wear and optimizes operating conditions. The exhaust simplifies maintenance thanks to the added holes on the flange. Finally, the silencer features more stable fixings, a racing-inspired aesthetic design, and unique customizations.

VITTORAZI MOTORS 250CC

(POR Marche FESR 2014-2020 Asse 1 - OS 1 - Azione 1.2)

Il progetto prevede, a partire da risultati di ricerca già acquisiti, l'ingegnerizzazione e l'industrializzazione di un nuovo prodotto..

Il progetto ha tra gli obiettivi: l'ingegnerizzazione e prototipazione esecutiva del nuovo motore, il miglioramento delle caratteristiche prestazionali e tecniche del prodotto, l'industrializzazione del nuovo motore, la promozione del prodotto innovativo e sviluppo della fase di commercializzazione per il nuovo mercato.

Ingegnerizzare, industrializzare e produrre il nuovo motore da proporre a un nuovo settore di clientela, acquisendo una fetta di mercato importante per lo sviluppo dell'impresa.

Investimento totale: 687.291,60 euro | Finanziamento pubblico: 337.675,80