17/04/2020

MOSTER 185 MY ’20 – RESISTANCE

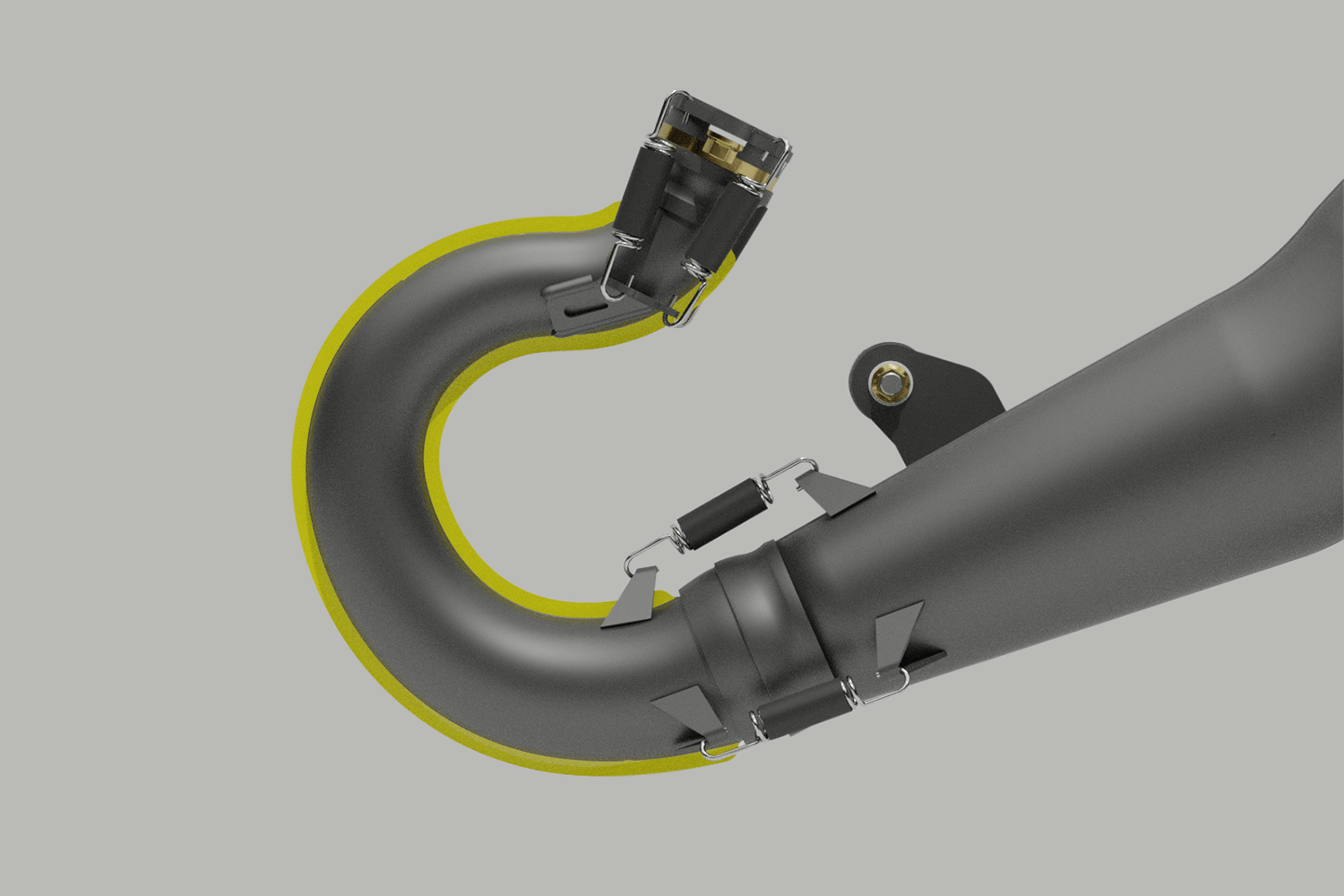

From the studies carried out on the exhaust, the need to strengthen the collector area was clear. A task that took time and research, because this is one of the most critical areas.

This is an important update, which was achieved thanks to in-depth research, working first on the computer to simulate mechanical stress, then carrying out load tests in the laboratory and finally stress tests on the test bench, to approve the studies previously carried out.

Different configurations have been tested for the lateral reinforcement of the collector part and different thicknesses of the sheet metal, with the aim of not making the exhaust too heavy, while still guaranteeing a high level of resistance.

The thickness of the sheet on the entire manifold has been increased and the welding chosen and applied, after several tests carried out, allowed us to obtain an optimal ratio between the weight and strength of the piece.

In addition, the ‘double rib’ welding system also guarantees a more stable and repeatable manufacturing process.