10/03/2016

NEW CLUTCH – MOSTER 185

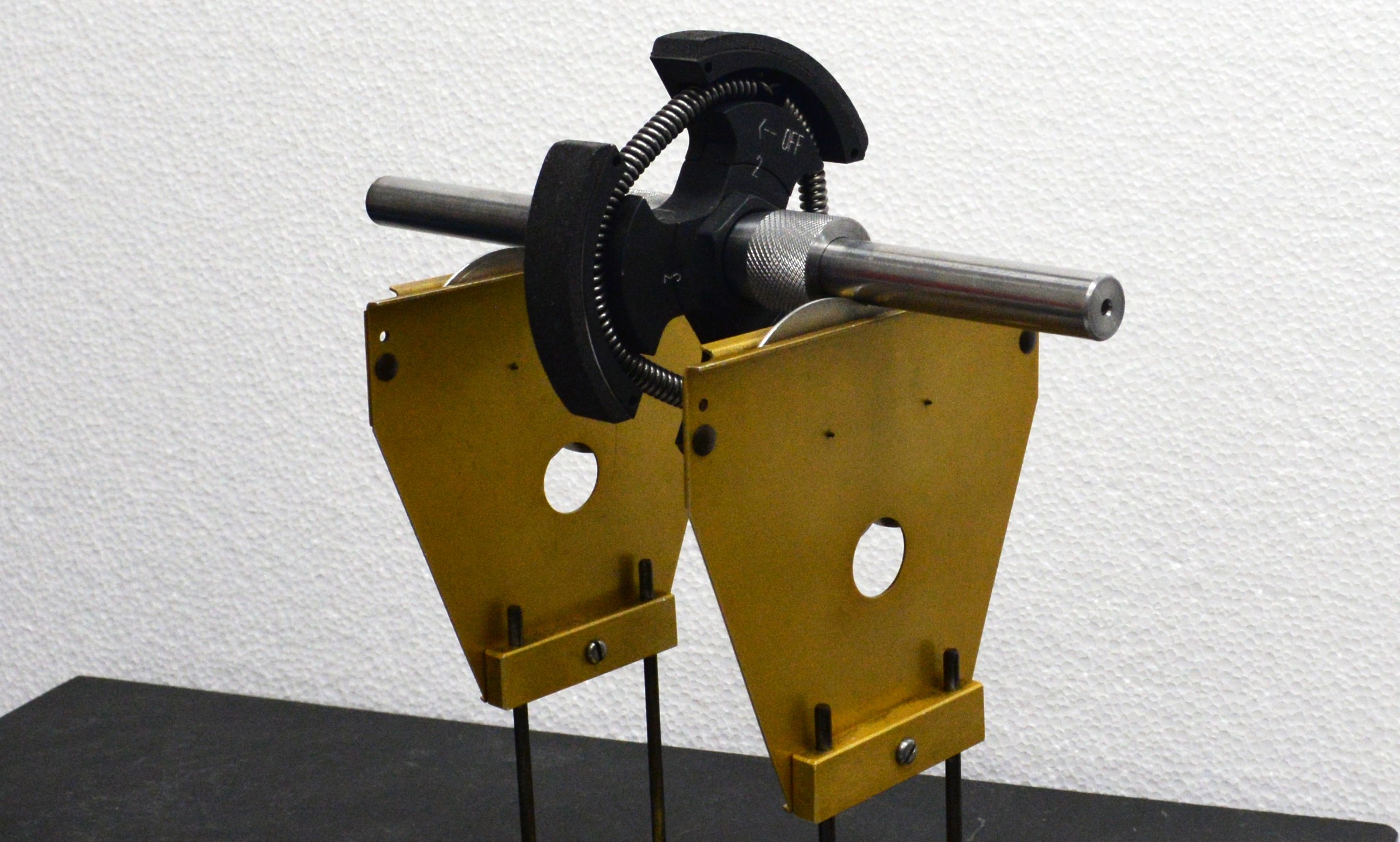

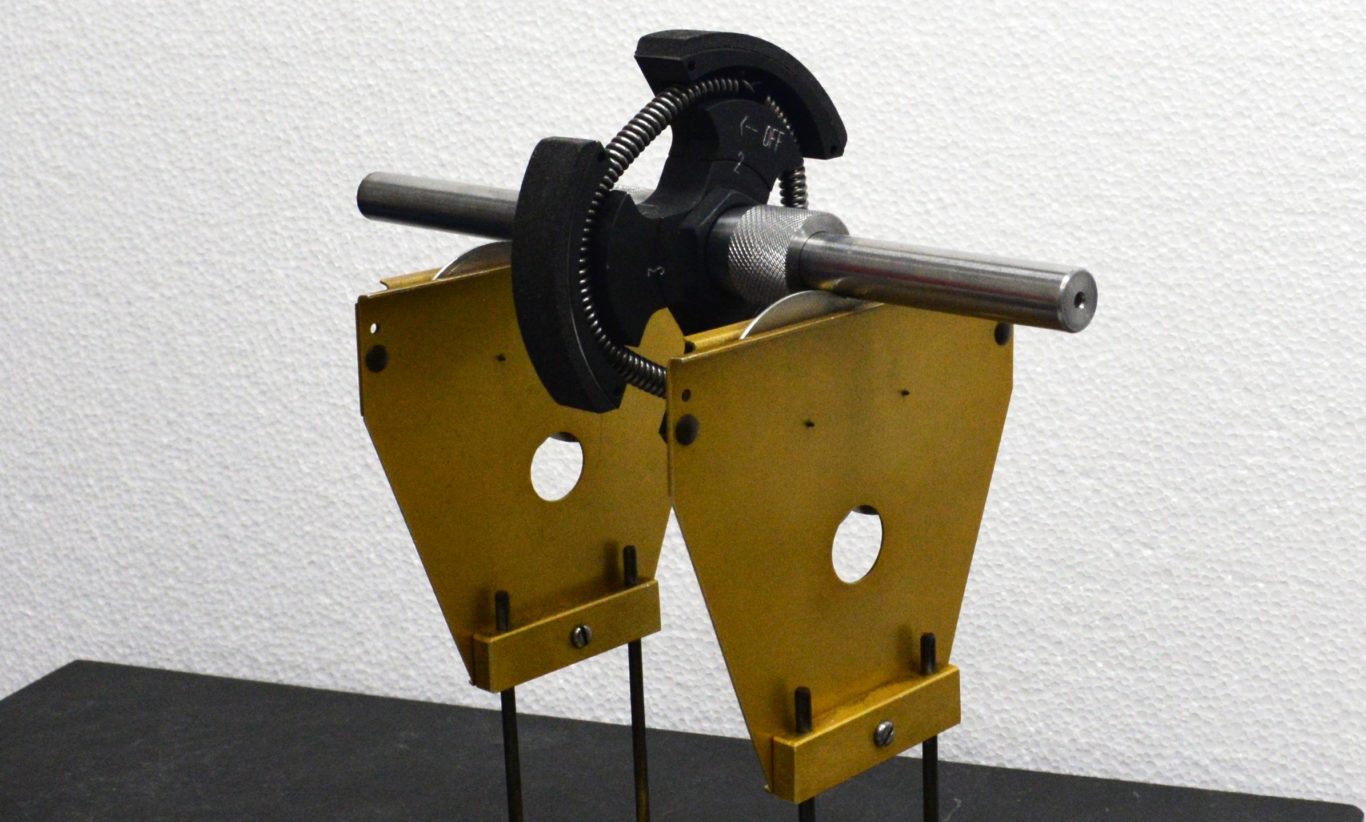

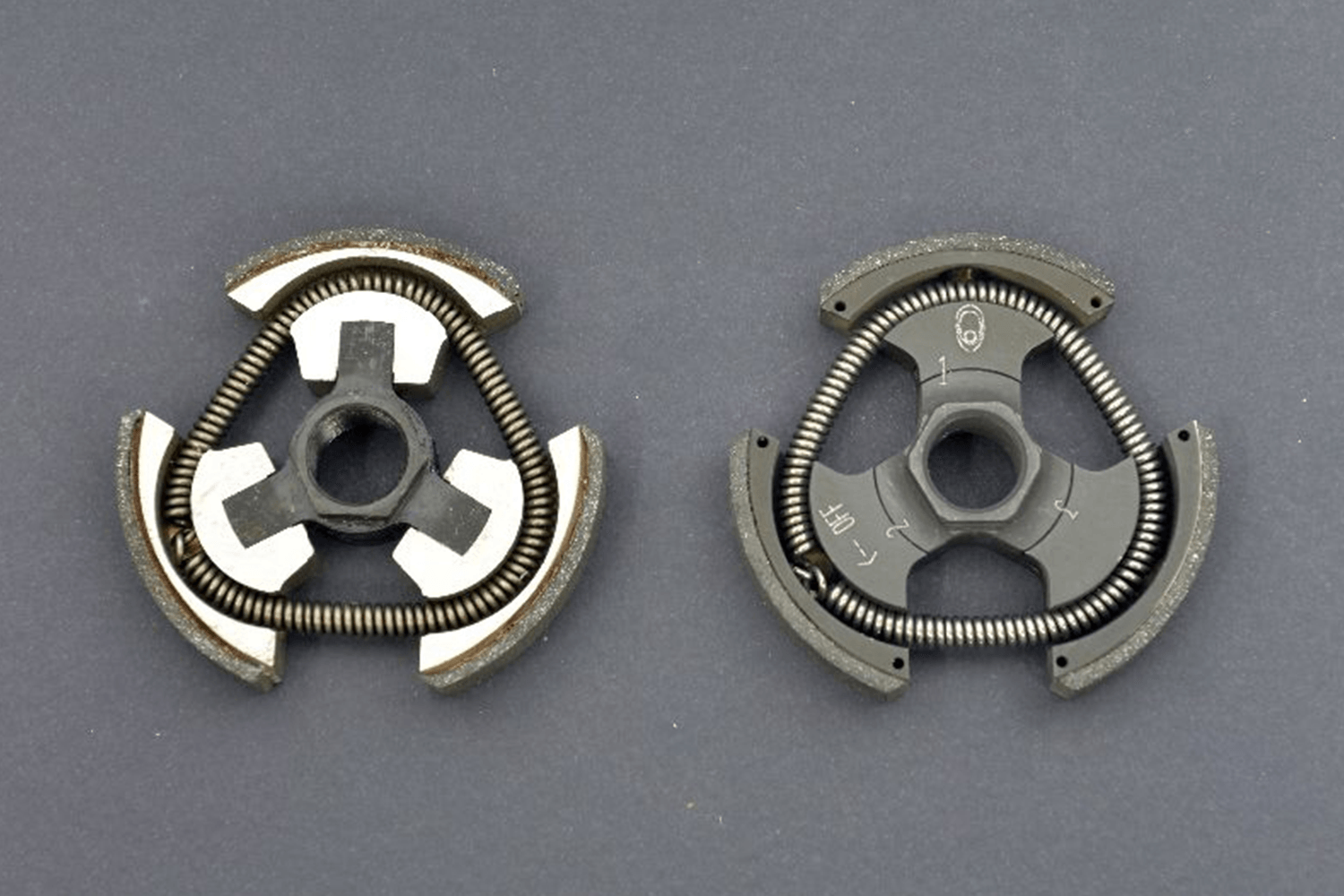

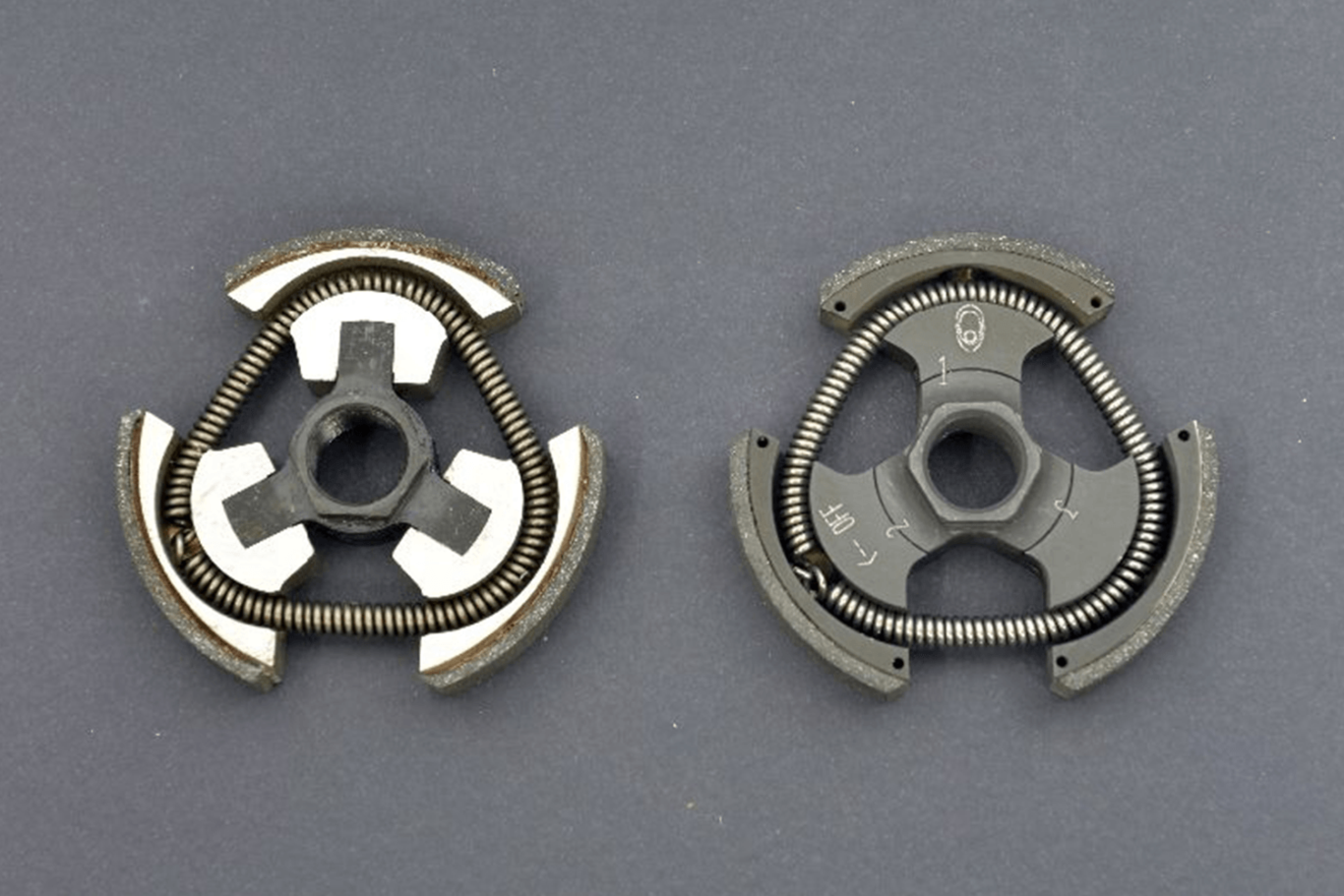

The Moster185Plus and Moster185Factory will be provided with a new, completely redesigned clutch, which will be launched parallel to Vittorazi’s Dark Evolution line.

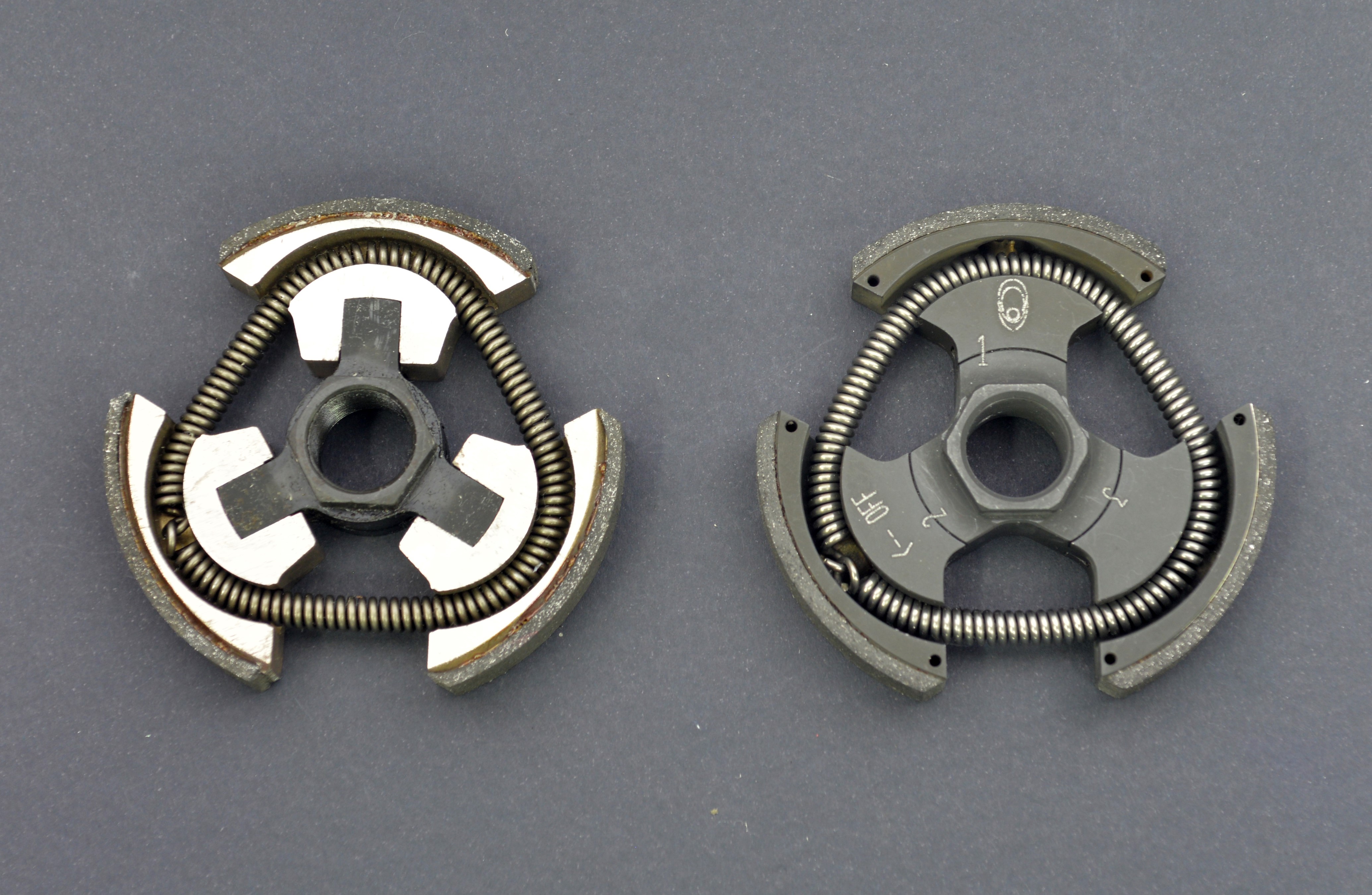

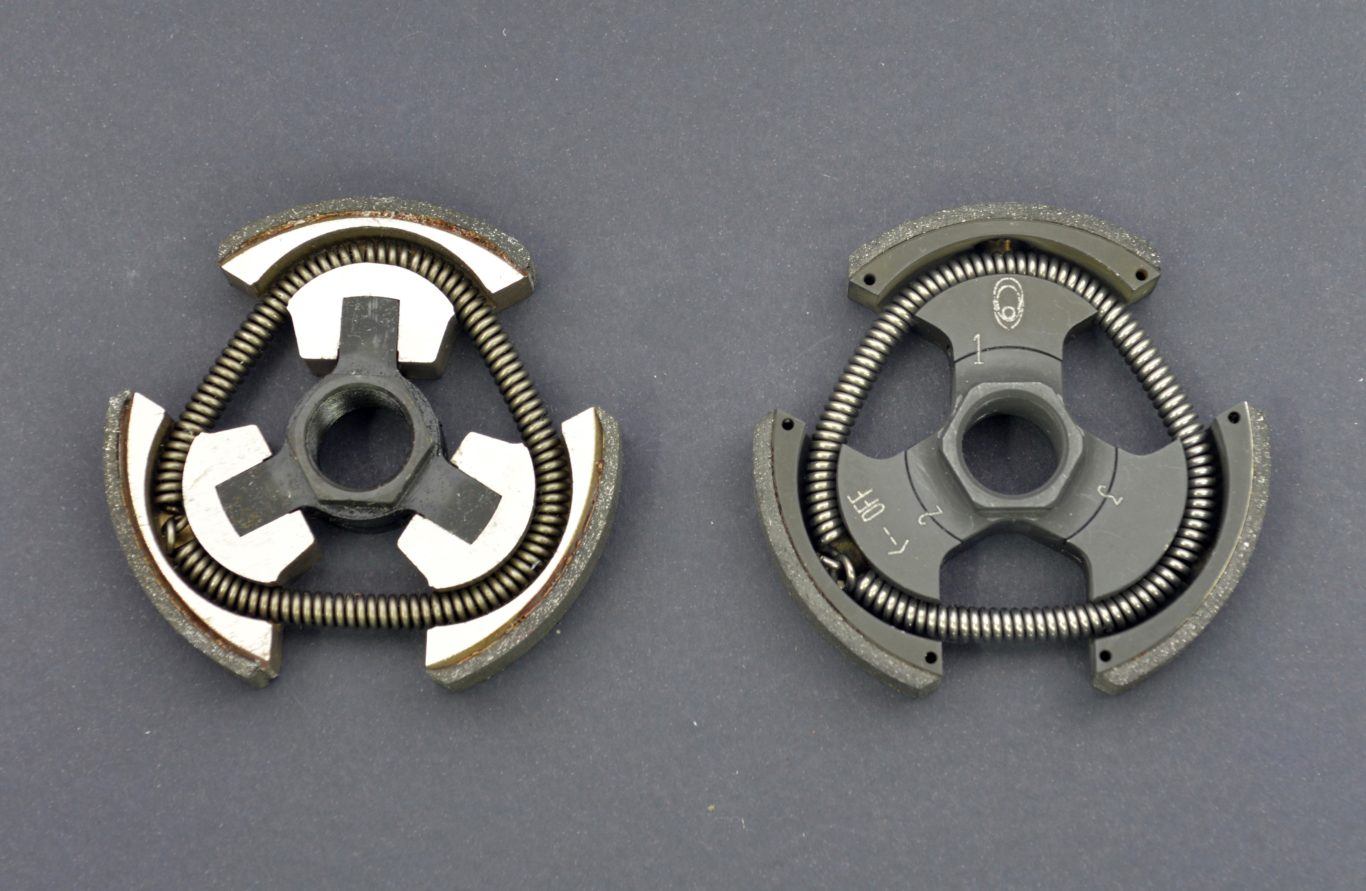

The new clutch is machined from solid. It is obtained through CNC machining of highly resistant alloy steel. It is very precise in geometry and, consequently, in weight. As these components rotate around the primary axle (more than 8000 RPM), the perfect balancing of the system is vital to reduce vibrations. Moreover, the significant reduction of “movements” between the elements plays an important role in the durability and in the absence of noises of the transmission.

During the testing phase of the components, the 3 clutch shoes are checked, numbered one by one and organized according to their size and weight (allowing only a minimal tolerance) and finally, before the installation, the whole clutch goes through a further check with balancing instruments.

The new clutch is 100% compatible with the previous versions and can be easily replaced with the help of a dealer or at any customer service centres. As for all Vittorazi products, this component has been tested for more than one year by their competition team and through trials, before being put on the market.