Cosmos300

THE LOOK OF POWER

Scroll down

THE LOOK OF POWER

MY25

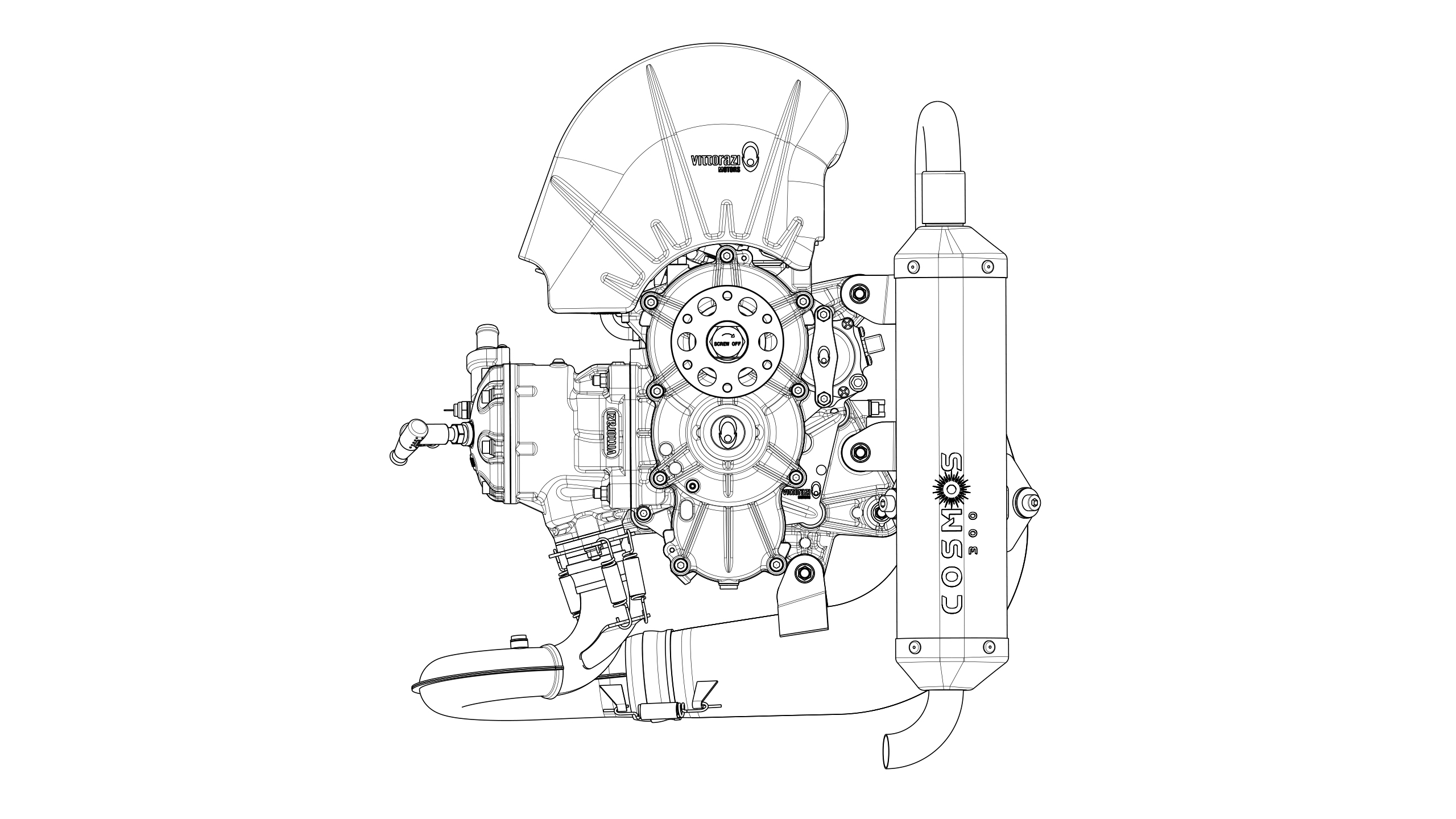

The Cosmos300 is an engine that pushes the boundaries of aeronautical engineering toward new horizons. Its name evokes infinity, symbolizing the dream of flying ever higher. With its larger displacement, this engine paves the way for new opportunities, confidently entering the markets for paratrikes, hang gliders, and minimalist ultralights. It is the engine of records, the star of incredible global achievements that only reinforce the quality of this product.

COMPACT DESIGN, GREAT VERSATILITY

Thanks to over 30 years of experience in paramotor design, the Cosmos300 combines a compact design and an optimized structure to deliver uncompromising performance. Every detail is carefully crafted to minimize size and bulk, ensuring a smooth airflow to the propeller and minimal vibrations. The Cosmos300 is a simple yet high-performance engine, and its robust and compact structure gives it a unique stability, making it a reliable engine in any condition. Its deep, immersive sound, together with low vibration, ensures a comfortable flight.

Scroll with your finger on the image

for 360° engine rotation

Show more

PERFORMANCE AND DURABILITY

Power, durability, and ease of maintenance are at the core of the Cosmos300. The first maintenance is required only after an impressive 100 flight hours, a testament to the exceptional build quality of this engine. Moreover, its components are designed to ensure long-lasting performance over time.

Cycle

2 strokes

Displacement

293,9 cc

Power

36 HP at 7.500 RPM

Air intake

Airbox silencer - Diaphragm carburettor, integrate choke system - Reed valve intake

Cooling system

Liquid cooling

Show more

Air intake system

The Cosmos300's airbox is the result of an in-depth flow analysis aimed at optimizing air velocity within and ensuring proper pressure delivery to the carburetor. The result is consistently steady power output, with quick restarts at any RPM and smooth accelerations. The Cosmos300 is equipped with a Tillotson diaphragm carburetor, which delivers maximum power, fuel efficiency, and consistent output even under challenging atmospheric conditions.

Twin spark

The aviation-derived Twin Spark technology ensures double the reliability with two independent ignition systems. The Cosmos300 is equipped with a coolant temperature sensor, which, together with the provision for the EGT (Exhaust Gas Temperature) probe, enables constant monitoring, optimal performance and flawless operation. The Cosmos300 MY25 features new shielded spark plug caps, which reduce electromagnetic interference typically generated by ignition systems.

Liquid cooling system

The Cosmos300's liquid cooling system keeps the temperature under control, preventing overheating and ensuring optimal performance. A dedicated mechanical pump ensures effective and reliable flow. The MY25 version introduces a more compact radiator, reducing weight and bulk without compromising performance. Alternatively, a configuration with the standard radiator positioned at the bottom is available, improving weight distribution and aerodynamics. Finally, Vittorazi graphic customization adds an exclusive touch to the design.

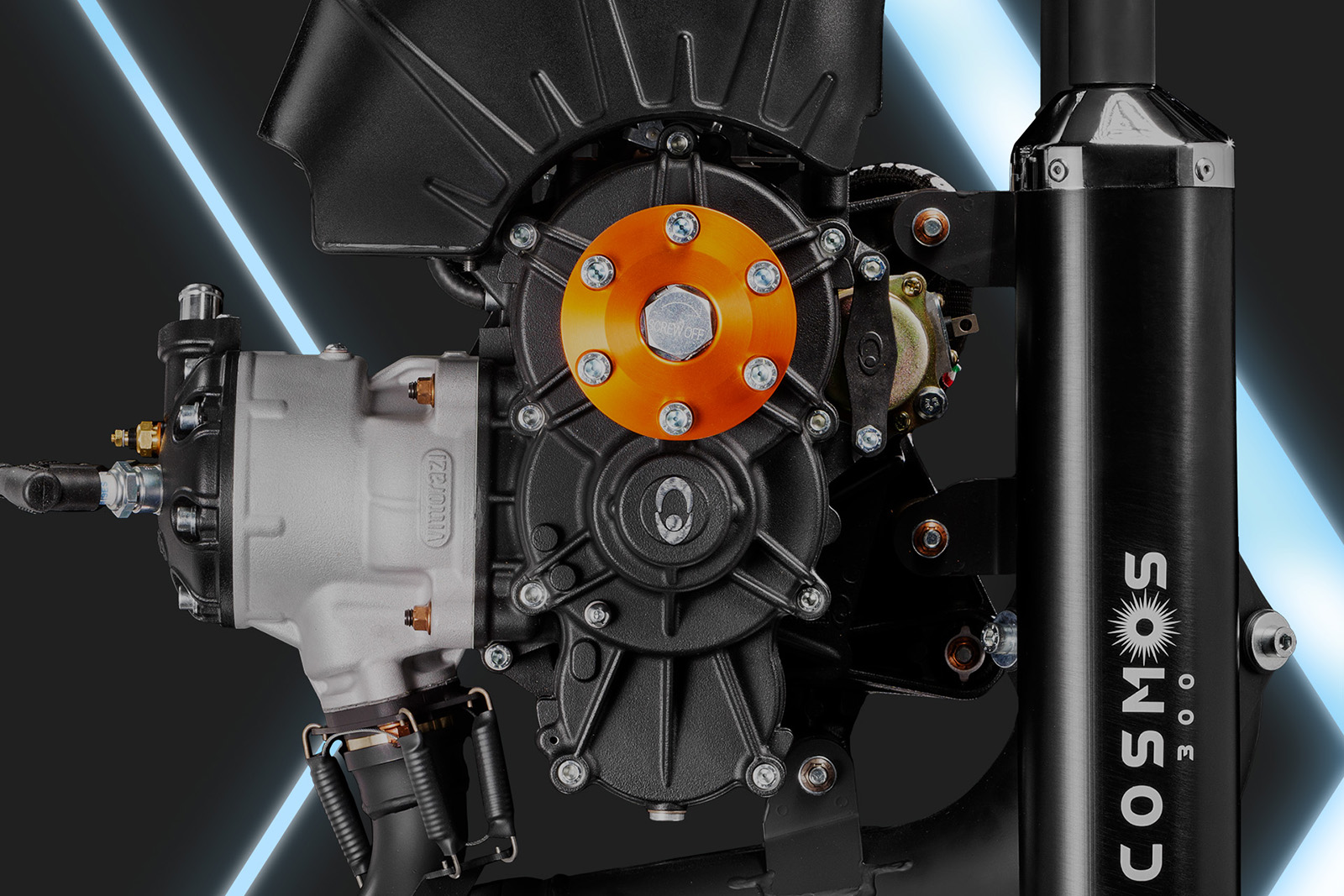

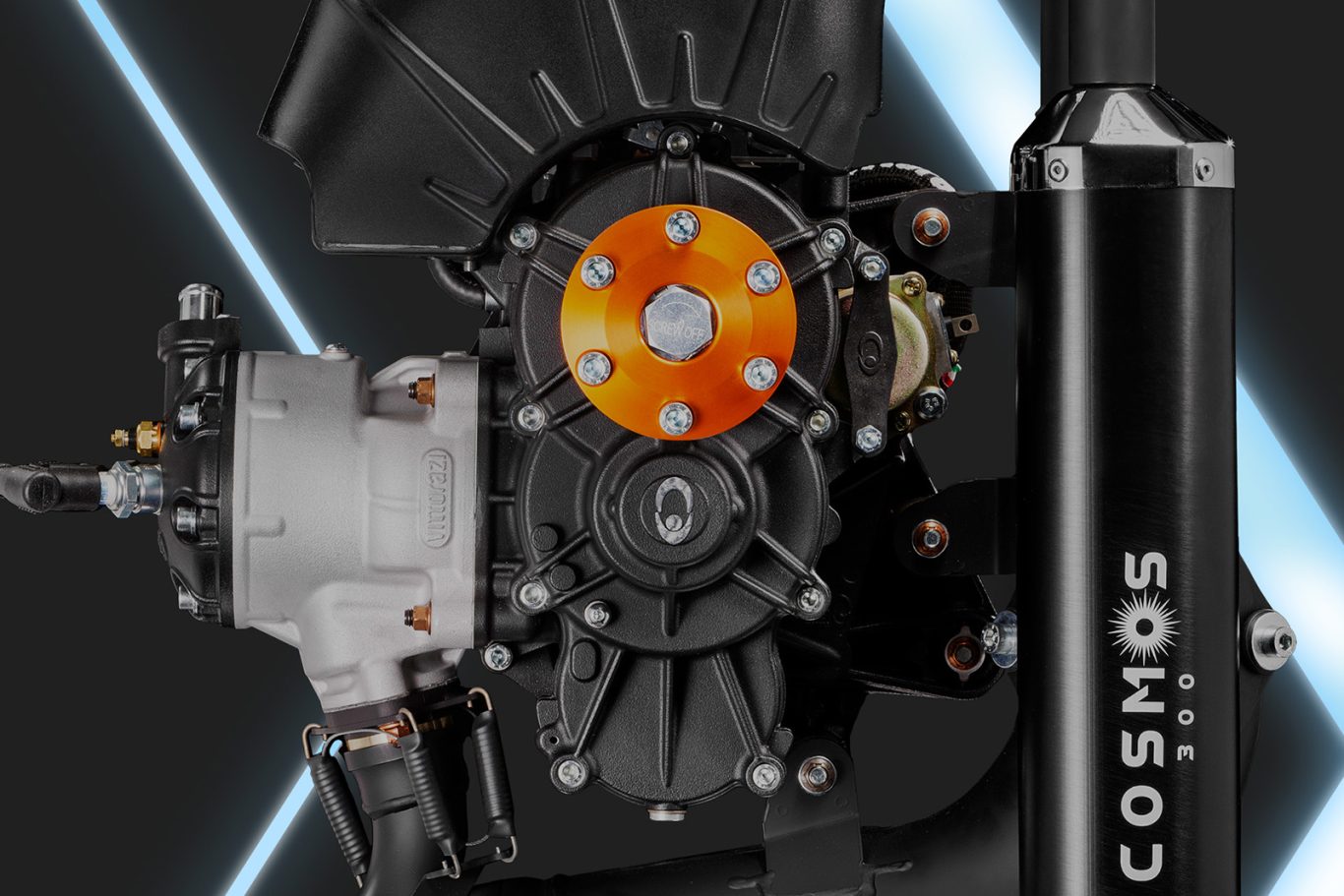

Transmission

The Cosmos300 represents advanced engineering: the front half casing houses the clutch, transmission, and countershaft, all immersed in an oil bath. The countershaft minimizes vibrations and stress, ensuring exceptional reliability.The straight-toothed gear transmission with Skiving surface finish delivers smooth power, thanks to low friction levels and optimal fluidity. At low RPMs, the clutch enhances comfort during ground operations.

Air intake system

The Cosmos300's airbox is the result of an in-depth flow analysis aimed at optimizing air velocity within and ensuring proper pressure delivery to the carburetor. The result is consistently steady power output, with quick restarts at any RPM and smooth accelerations. The Cosmos300 is equipped with a Tillotson diaphragm carburetor, which delivers maximum power, fuel efficiency, and consistent output even under challenging atmospheric conditions.

Twin spark

The aviation-derived Twin Spark technology ensures double the reliability with two independent ignition systems. The Cosmos300 is equipped with a coolant temperature sensor, which, together with the provision for the EGT (Exhaust Gas Temperature) probe, enables constant monitoring, optimal performance and flawless operation. The Cosmos300 MY25 features new shielded spark plug caps, which reduce electromagnetic interference typically generated by ignition systems.

Liquid cooling system

The Cosmos300's liquid cooling system keeps the temperature under control, preventing overheating and ensuring optimal performance. A dedicated mechanical pump ensures effective and reliable flow. The MY25 version introduces a more compact radiator, reducing weight and bulk without compromising performance. Alternatively, a configuration with the standard radiator positioned at the bottom is available, improving weight distribution and aerodynamics. Finally, Vittorazi graphic customization adds an exclusive touch to the design.

Transmission

The Cosmos300 represents advanced engineering: the front half casing houses the clutch, transmission, and countershaft, all immersed in an oil bath. The countershaft minimizes vibrations and stress, ensuring exceptional reliability.The straight-toothed gear transmission with Skiving surface finish delivers smooth power, thanks to low friction levels and optimal fluidity. At low RPMs, the clutch enhances comfort during ground operations.

VITTORAZI MOTORS 250CC

(POR Marche FESR 2014-2020 Asse 1 - OS 1 - Azione 1.2)

Il progetto prevede, a partire da risultati di ricerca già acquisiti, l'ingegnerizzazione e l'industrializzazione di un nuovo prodotto..

Il progetto ha tra gli obiettivi: l'ingegnerizzazione e prototipazione esecutiva del nuovo motore, il miglioramento delle caratteristiche prestazionali e tecniche del prodotto, l'industrializzazione del nuovo motore, la promozione del prodotto innovativo e sviluppo della fase di commercializzazione per il nuovo mercato.

Ingegnerizzare, industrializzare e produrre il nuovo motore da proporre a un nuovo settore di clientela, acquisendo una fetta di mercato importante per lo sviluppo dell'impresa.

Investimento totale: 687.291,60 euro | Finanziamento pubblico: 337.675,80