30/09/2012

Dynamic propeller balancing for paramotor – Vittorazi Motors

The dynamic balancing of the propeller is a very often neglected operation in the correct tuning of a paramotor; although the advantages it offers are well known, it is almost always omitted and replaced by the simplest statical balancing.

It is assumed that, being a propeller statically balanced, it does not produce vibrations: in reality there is no rotating body that does not produce vibrations.

In a paramotor the potential sources of vibration are many: the piston, the drive shaft and the bearings in the drive unit, the gearbox, the silent blocks, the transmission shaft, the propeller, etc…

If these vibrations by pure coincidence cancel each other out, the resulting vibration may be low, but if, as is more often the case, the vibrations add up, this results in an excessive level that is often difficult for the rider to perceive.

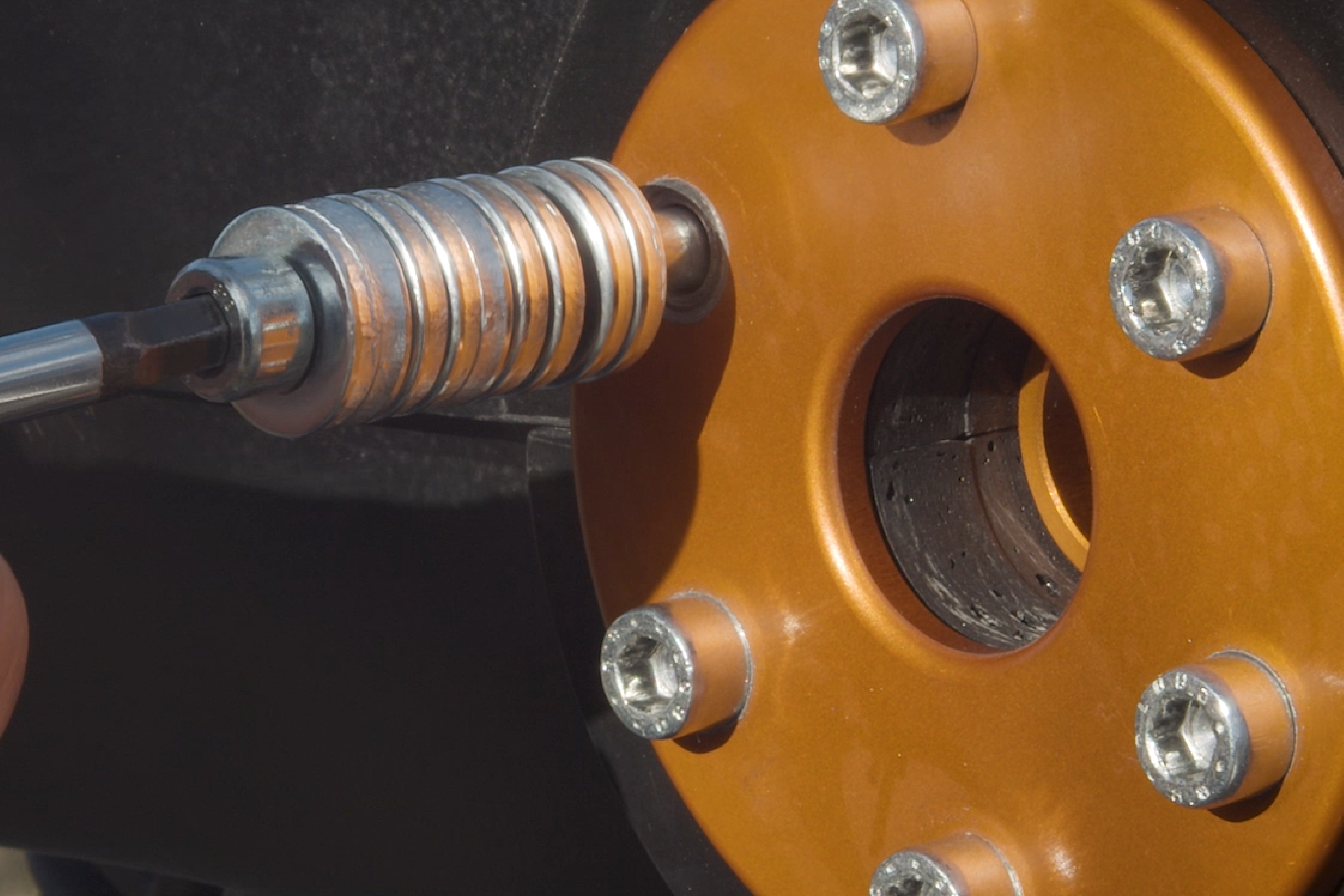

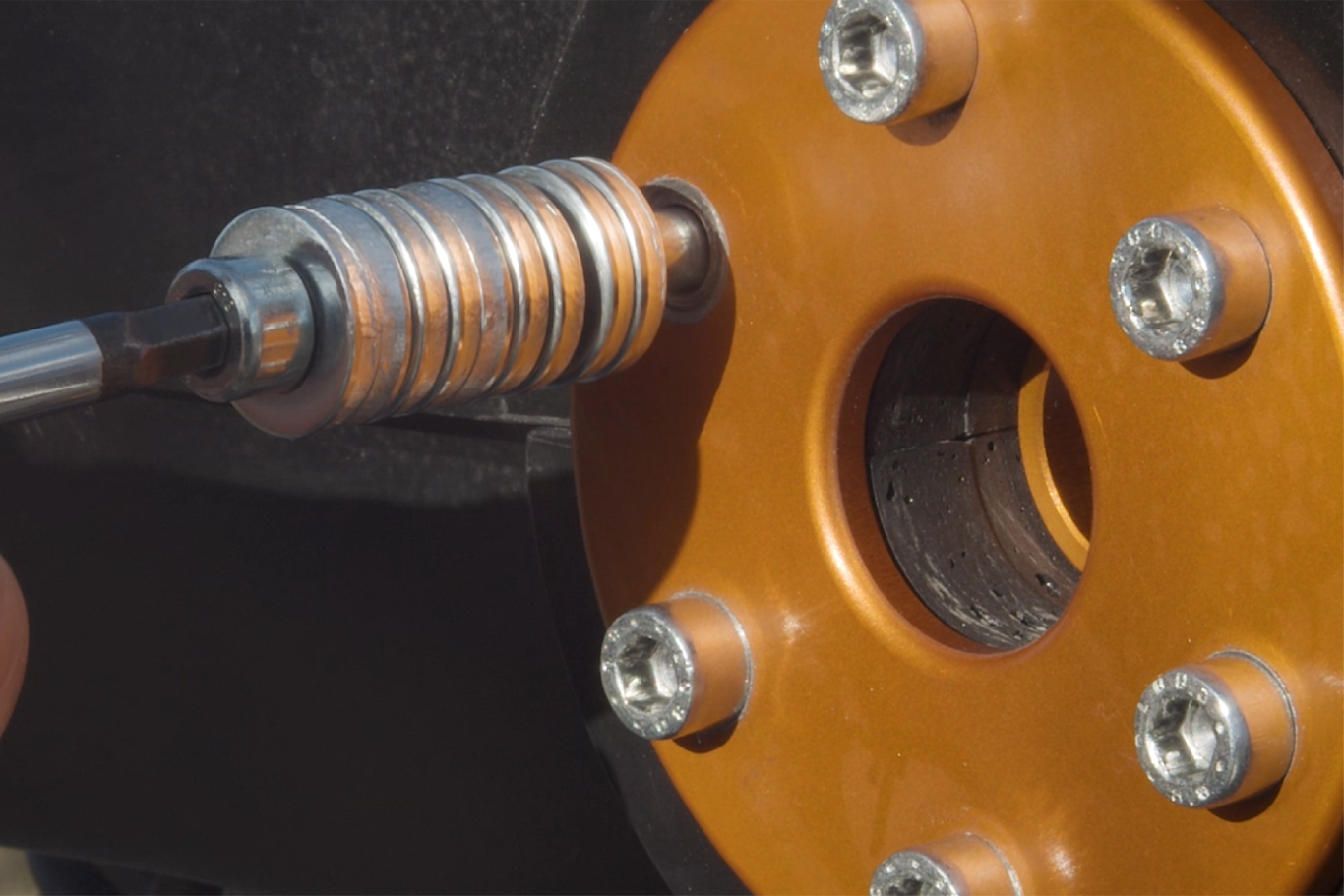

Dynamic balancing can therefore be defined as the process in which an analyzer is used.

electronic to measure the level of vibration produced by the drive unit on an aircraft. It is carried out directly on the vehicle, ready to fly. The engine is started, and the signals are detected by the analyzer at cruising speed.

The balancing of a rotating mass is therefore highly recommended to obtain one or more of the following advantages: improved comfort, reduced vibration, lower noise level, minimized structural stress, longer bearing life, reduced power loss.

The “Vittorazi Motors” has developed, in collaboration with “MG Solutions”, the use of such analysis techniques dedicated more to the rotary wing, but also to the paramotor.

A correctly balanced paramotor is essential for safety, performance and comfort. Dynamic balancing is an easy operation today, at negligible costs compared to the advantages it offers and the value of the vehicle. It should be carried out on the new vehicle and every time a replacement/revision of the motor/propeller assembly or one of its rotating components is made.

The result will be, in the end, a decisive increase in driving pleasure and higher and higher performance.