19/06/2015

MOSTER 185 – THE LATEST INNOVATIONS

Moster 185 improvements.

1. New carter, new carter support: lighter, stronger, better performing.

Thanks to the development of the engine Moster 185 Factory, which showed significant improvements in terms of lightness, reliability and performance, Vittorazi choose to extend some improvements to the production of the standard Moster 185 engine range (Moster185 Classic, Silent, Plus) by adopting the same geometry for crankcase and engine support.

These components are made of cast aluminum, then tempered and finally worked on CNC machines. As for the model “Factory”, a series of fins and radial ribs have allowed a weight reduction of 10%, whilst reducing the temperatures, dilatations or torsion of the crankcase.

Specifically it has been further reinforced the areas of the reduction support and the arms of the carter support, with the aim to increase the endurance of the components in case of crash of the propeller to the ground.

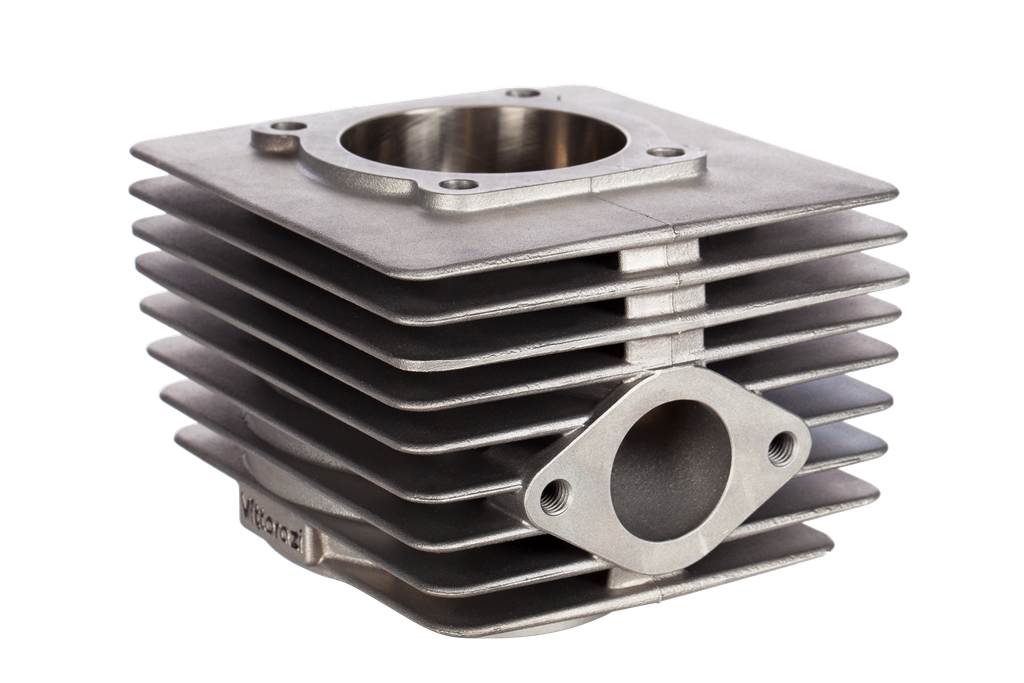

Yet another improvement has been achieved in the crankcase geometry (new transfer ports) which together with the new cylinder, have allowed an increase of performance and power.

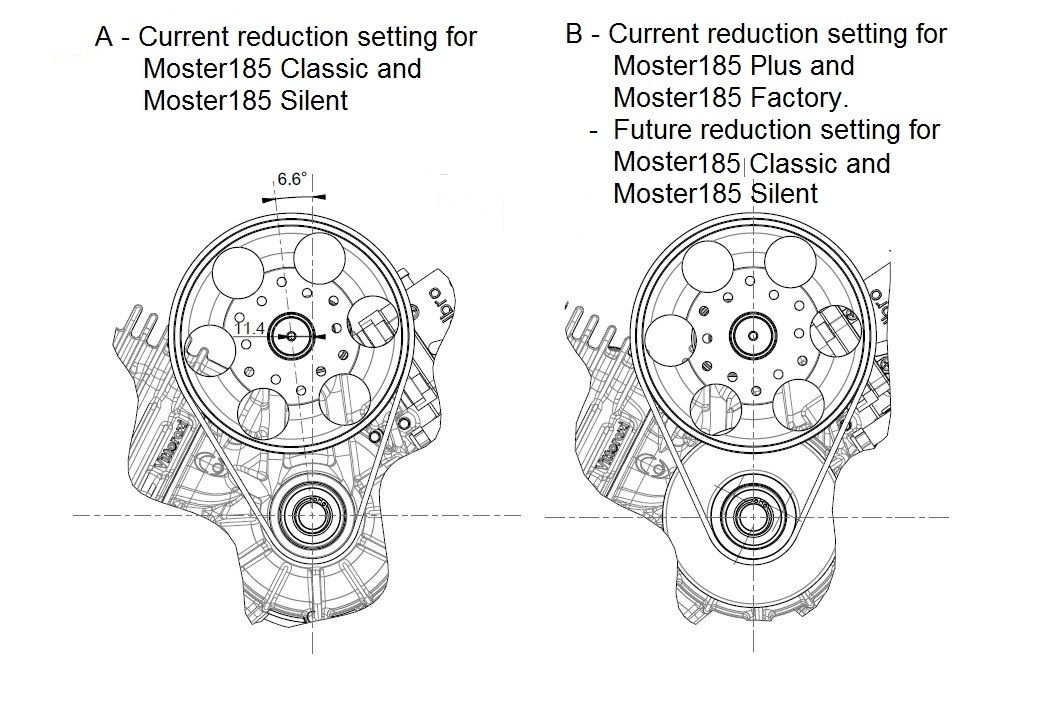

The position of the propeller shaft (eccentric shaft) has been rotated to increase the ventilation of the cylinder and to outdistance the pulley and the belt from the fins.

It was found that the reduction belt and the reduction bearings last longer (up to 100 operating hours in the engine Moster 185 plus).

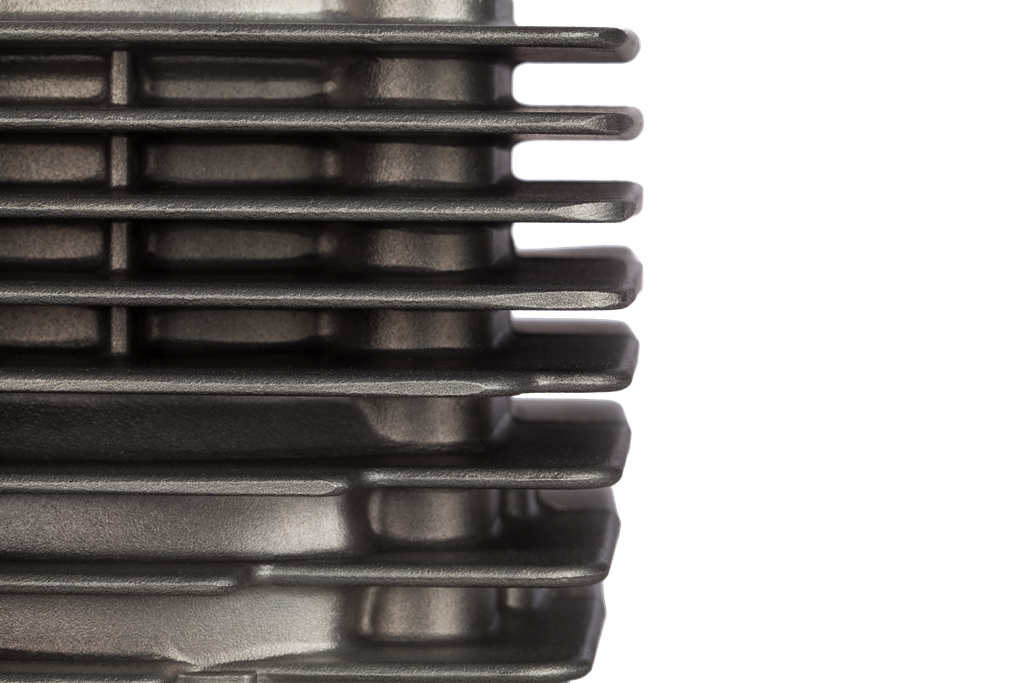

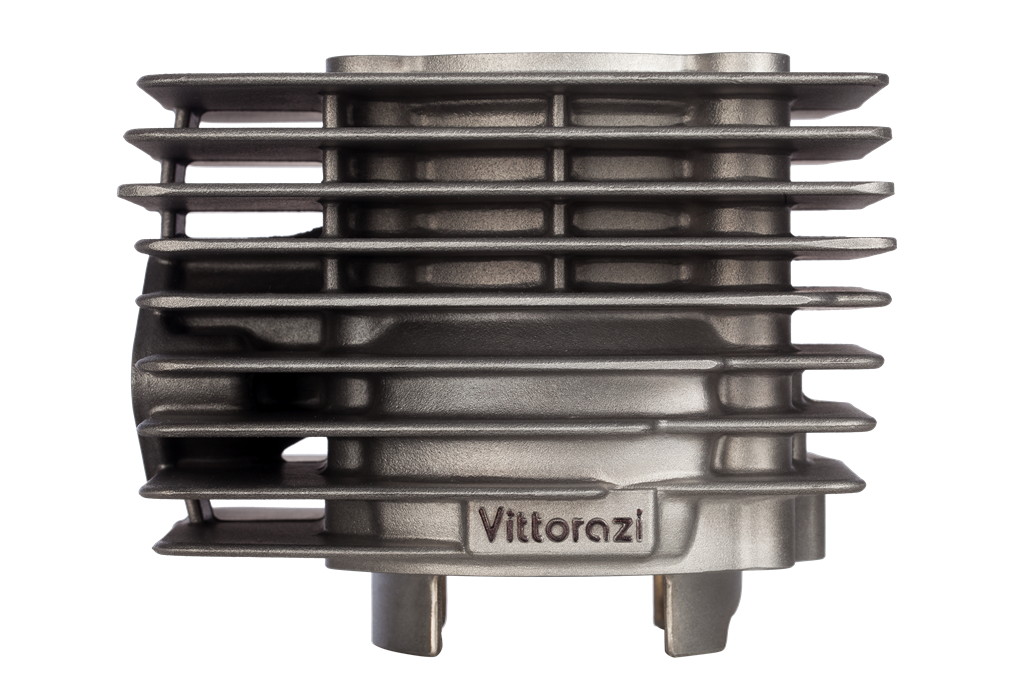

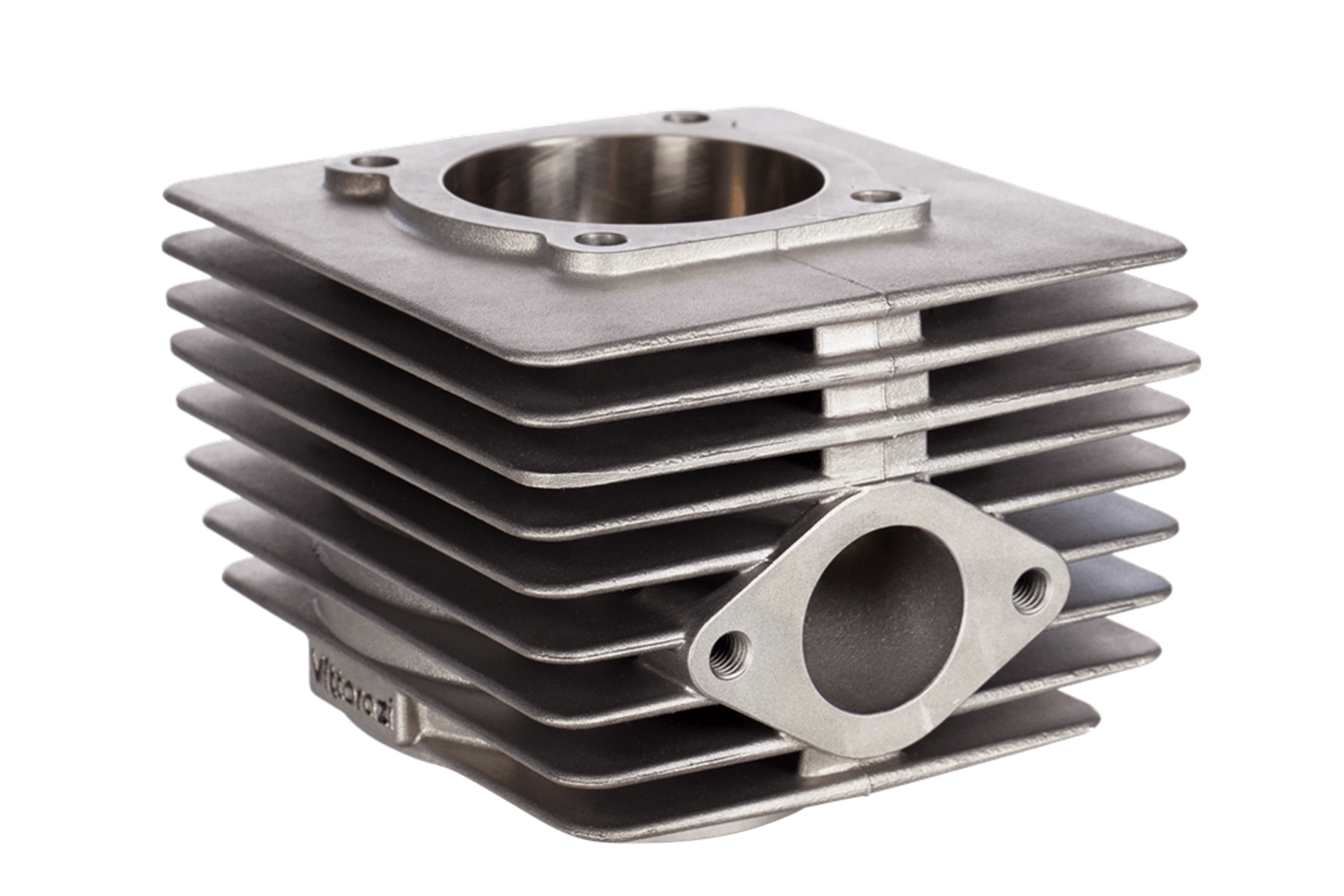

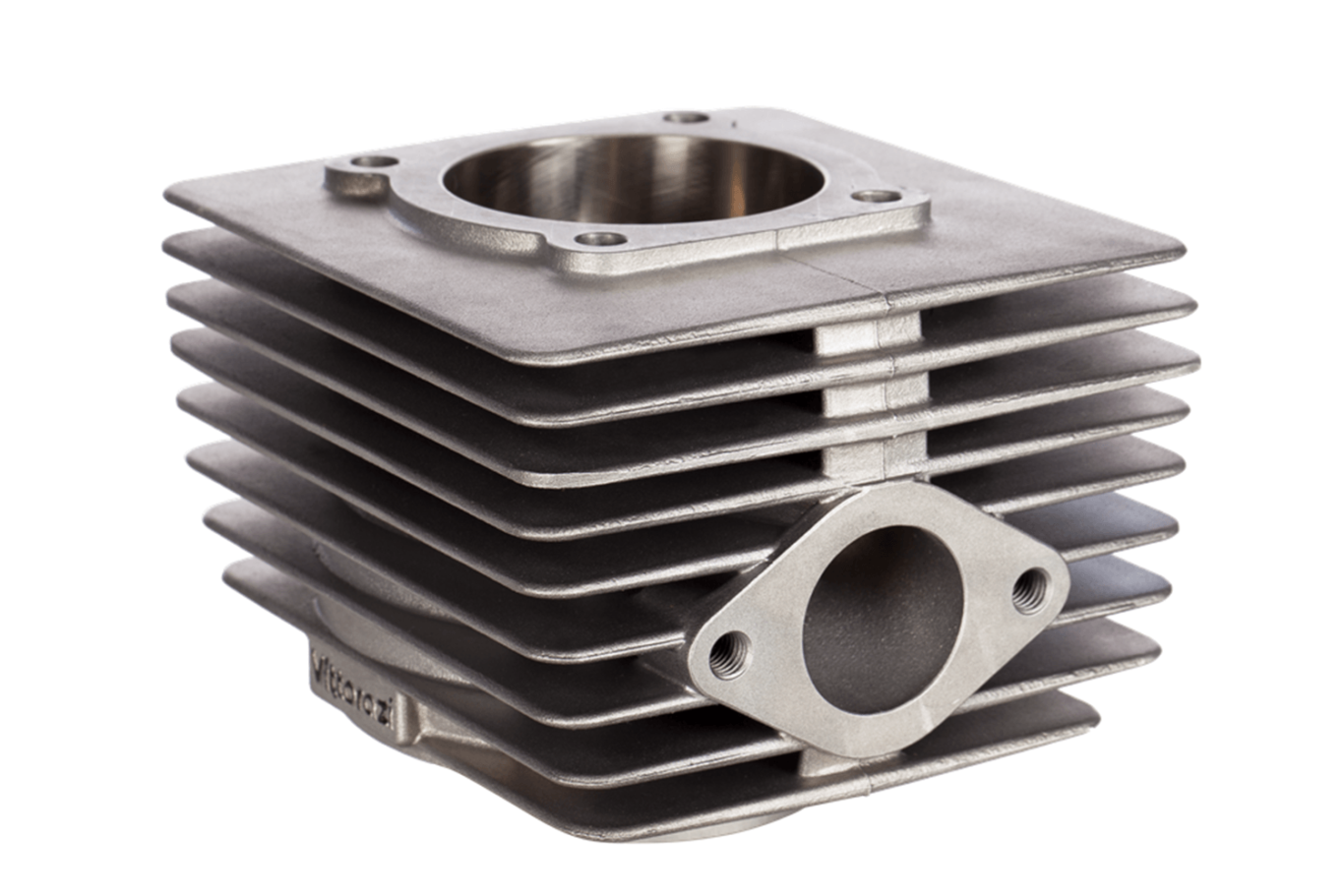

Besides the crankcase, also the new cylinder used on all Moster185 models, provides an overall performance improvement:

– reduction of operating temperatures, thanks to an increased heat exchange surface (one fin added);

– homogeneity of the temperatures of the thermic unit, thanks to the new layout of the fins;

– increase in power, reduction in fuel consumption and noise emissions, arising from advanced studies on the fluid dynamics

of the intake and exhaust.

– Despite these improvements, the cylinder’s mass decreased by 10%, the life of the thermic unit’s components has increased and the comfort of flight, in combination with the “silent” exhaust, is significantly improved.

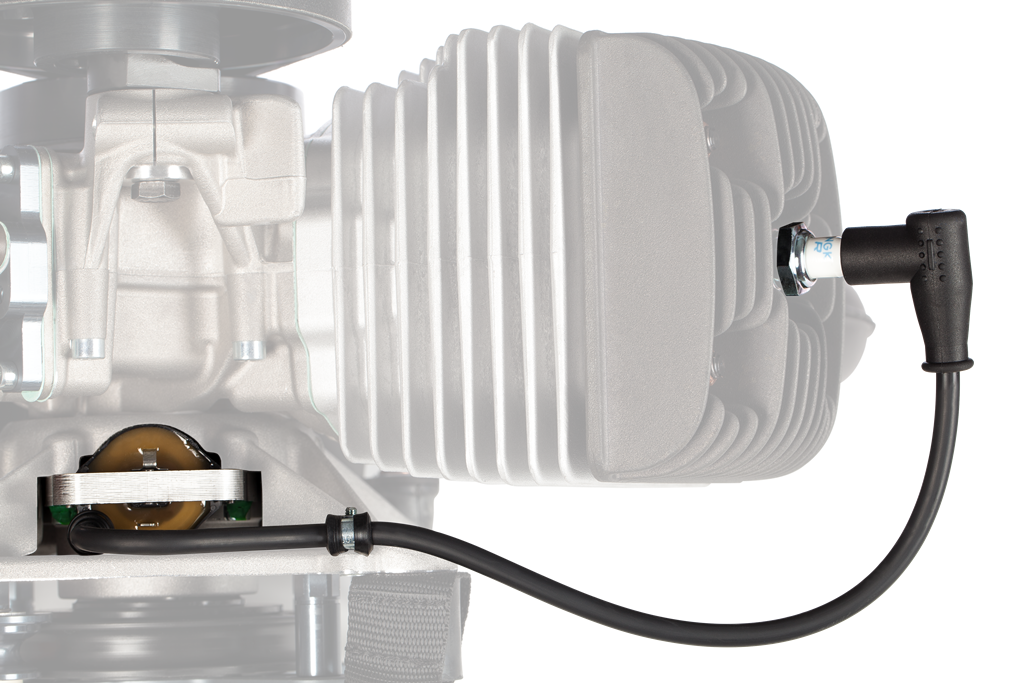

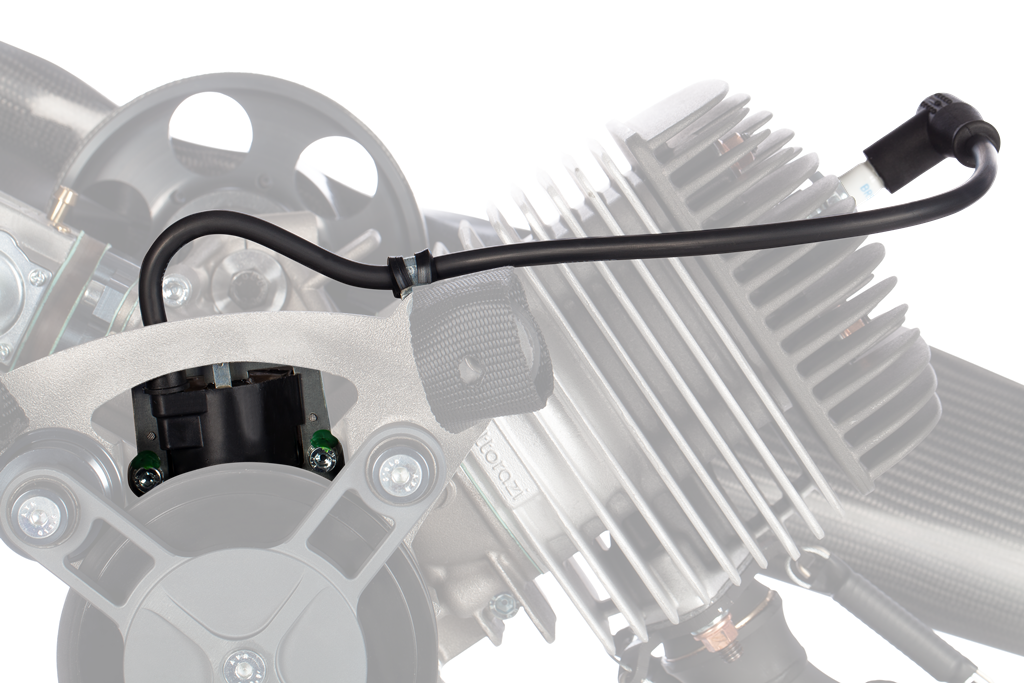

2. Ignition coil Selettra.

The quality of the new electronics, in addition to a performance increase, offers greater reliability, safety and a longer life.

The new flywheel-coil ignition group by Selettra, historic Italian Vittorazi Motors supplier since 1995 for the 80cc engine, allows a better starting of the engine both when it is cold or hot.

Increased is the robustness of the high voltage cable (from 5 to 7mm) as well as improved is the cable support and the material of the spark plug cap. The aluminum toothed pulley and the flywheel are embedded in favour of simplicity and lightness.

All of the solutions listed above, in addition to new E-props propeller for which it has been dedicated a separate news, have been taken into consideration since the beginning of 2014 and have been tested for over a year by the Vittorazi racing and testing team.