Discover all the innovations of the new MY25 release.

The Moster185 Factory-R is synonymous with high performance and unique design. It is a product of pure excellence, featuring top-level high-tech components such as titanium hardware, carbon fiber parts, chrome finishes, and CNC machined from solid components. The Moster185 Factory-R boasts a highly recognizable and captivating aesthetic. The engine is available in six different colors: red, orange, gold, silver, green, and blue. Choose your color and unleash your power. This engine embodies a true racing spirit, designed for pilots who seek top-tier performance and love flying with a premium product.

The MY25 version stands out with a series of upgrades that further enhance its quality, durability, ease of maintenance, performance, and comfort. Every detail has been refined to deliver a unique product capable of meeting the demands of professionals and the most demanding pilots.

Let’s explore all the new features together.

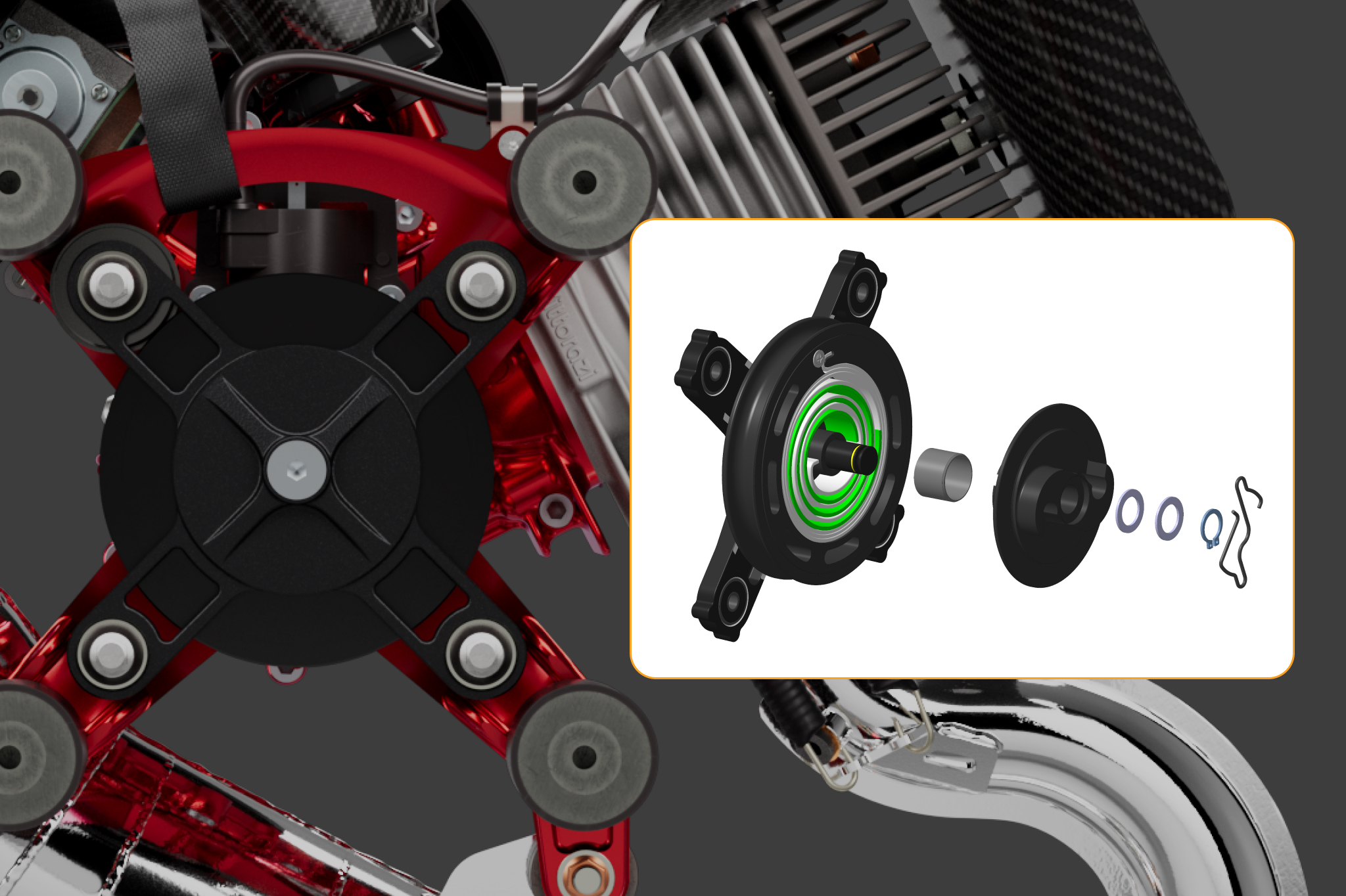

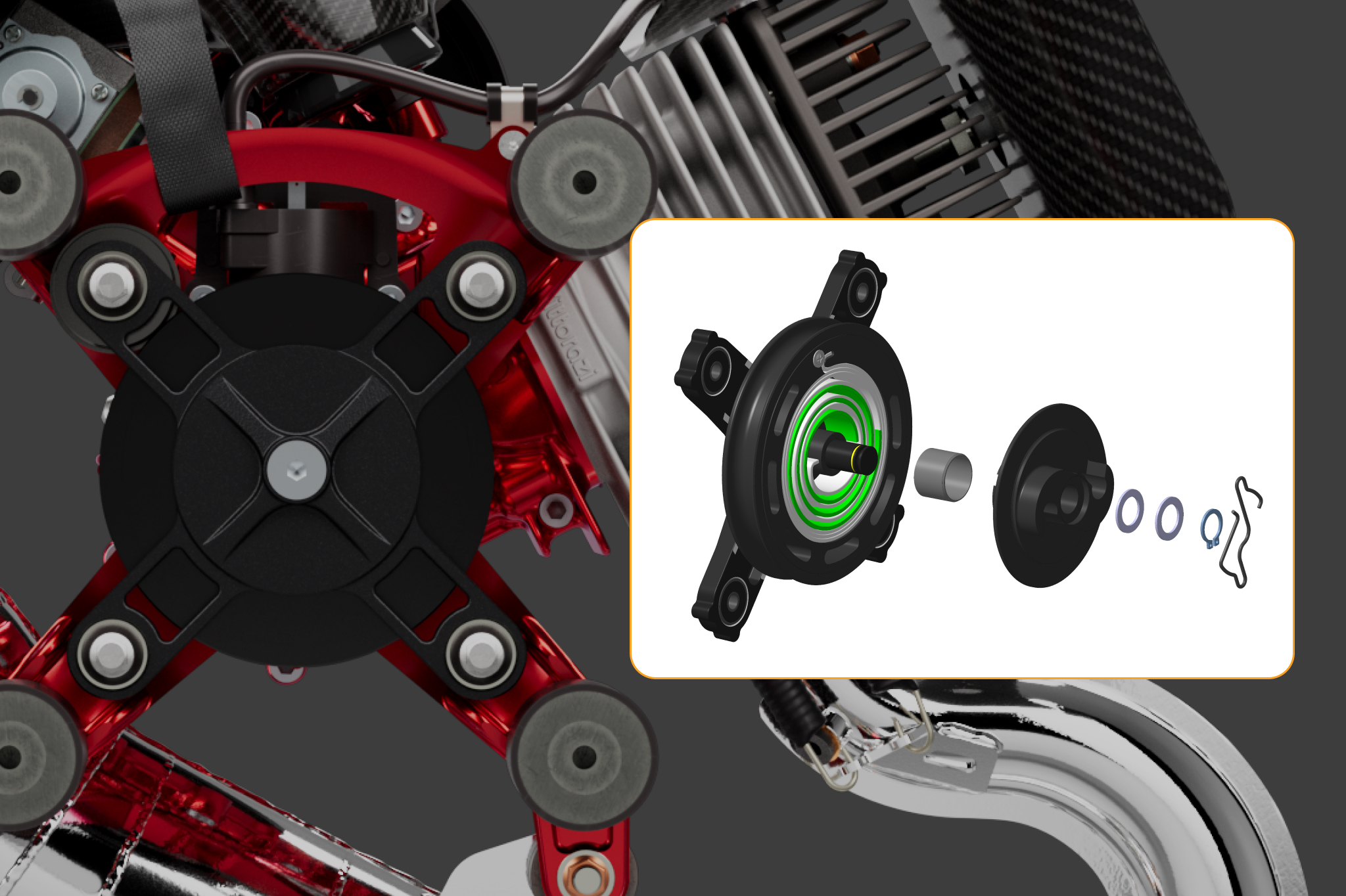

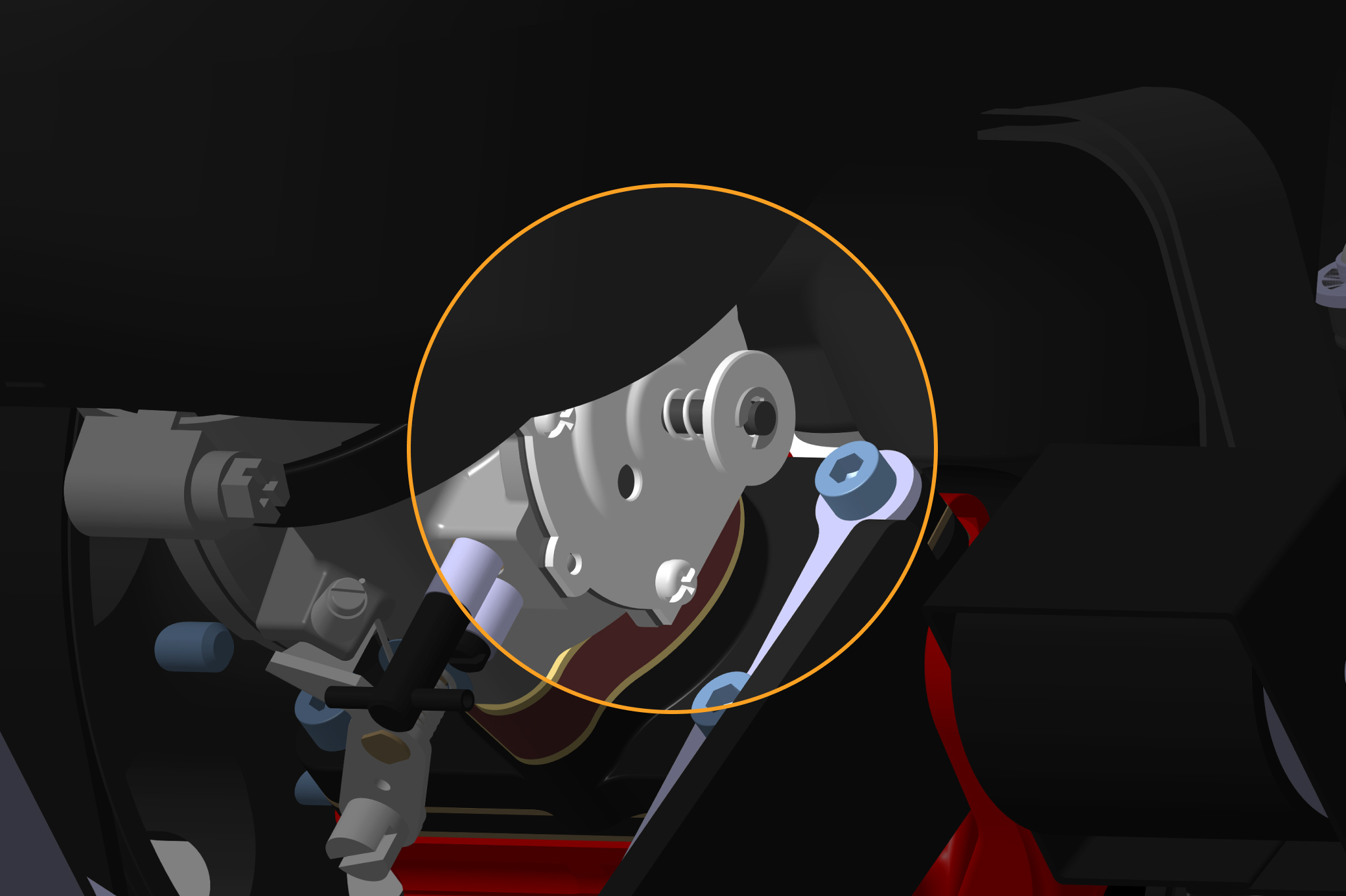

Optimized Pull-Start System

The new pull-start system of the Moster185 Factory-R MY25 features a self-lubricating bushing positioned between the pulley and pawl housing. This integration improves sliding and reduces mechanical play, ensuring stable and precise operation even in the presence of vibrations and high temperatures. This component extends the system’s lifespan, minimizing wear and overheating. The addition of a retaining screw for the “easy starter” spring, designed to keep the spring securely in place, prevents unwanted movements, while the insertion of a Seeger-Ring ensures smooth and long-lasting movement of the pawl spring. This component acts as a buffer, minimizing friction and stress that would otherwise affect the pawl system. The result is greater durability, smoother operation, a more precise engagement, and optimized safety against potential issues. With the evolution of these components, the Moster185 Factory-R MY25 not only performs well under standard conditions but also withstands extraordinary situations such as poor maintenance, adverse weather conditions, and improper use. A significant improvement for this new MY25 version. This evolutionary step contributes to a pleasant and long-lasting flight experience while offering greater tolerance to actions that may not always align with the maintenance manual, even from less meticulous pilots.

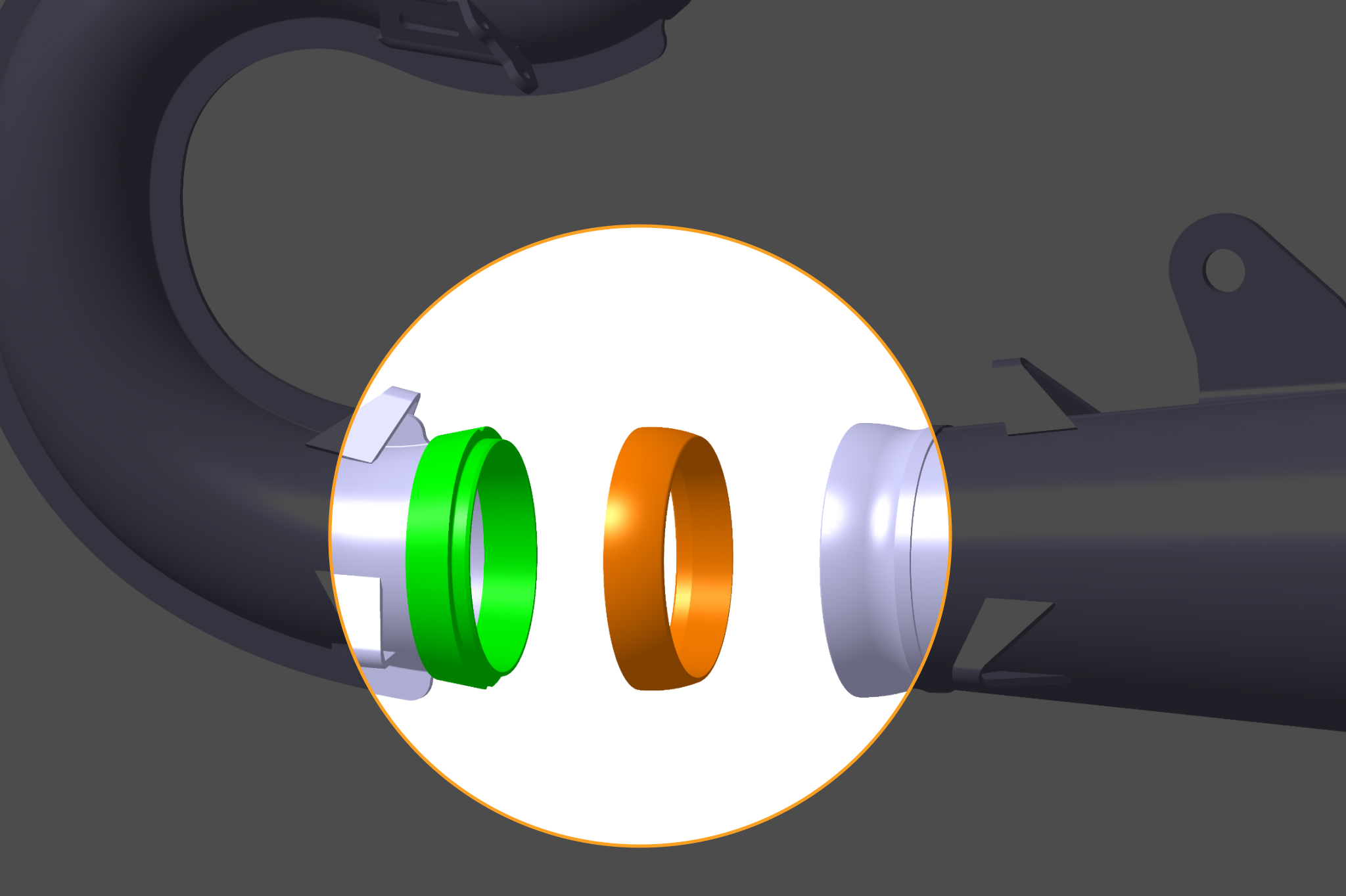

Second self-lubricating bronze bushing

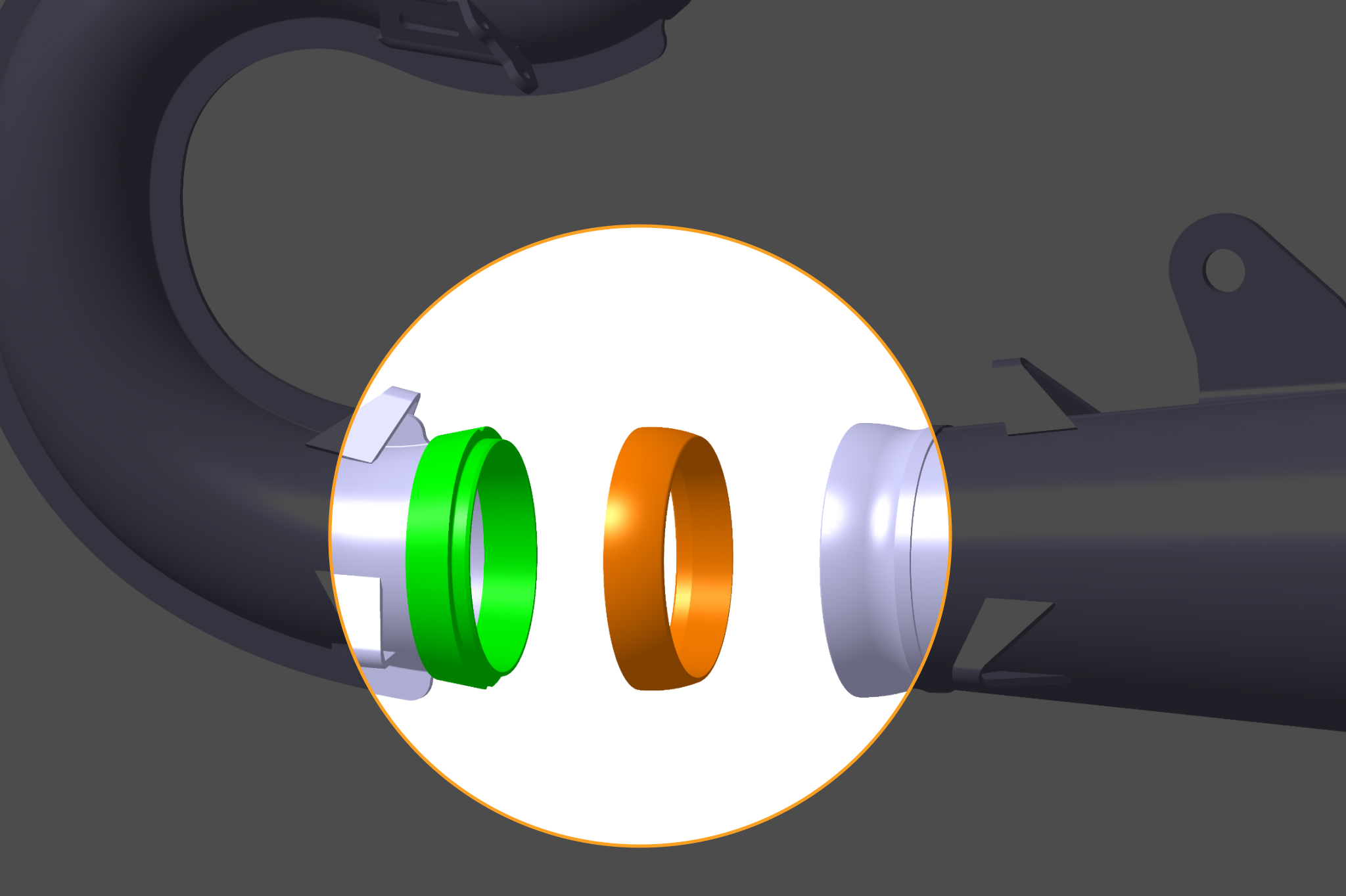

The manifold of the new Moster185 Factory-R MY25 has been updated with the addition of a second self-lubricating bronze bushing, which minimizes friction between the manifold and the muffler, allowing smoother movement and reducing the risk of seizing. This update protects the manifold from mechanical stress, prolonging its lifespan and improving system efficiency. In this way, the Moster185 Factory-R MY25 reaches the same level of excellence as the Moster185 EFI improvements.

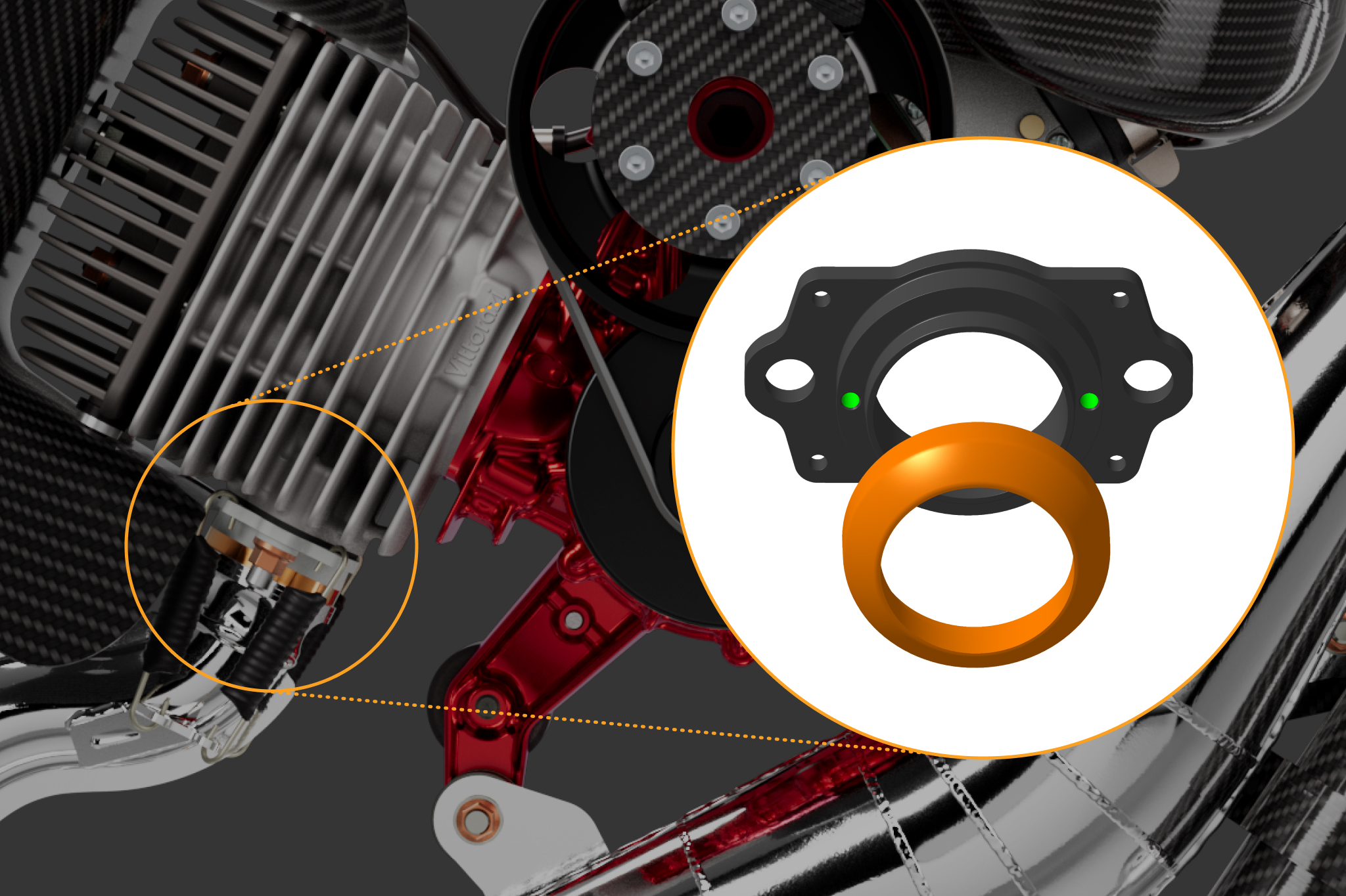

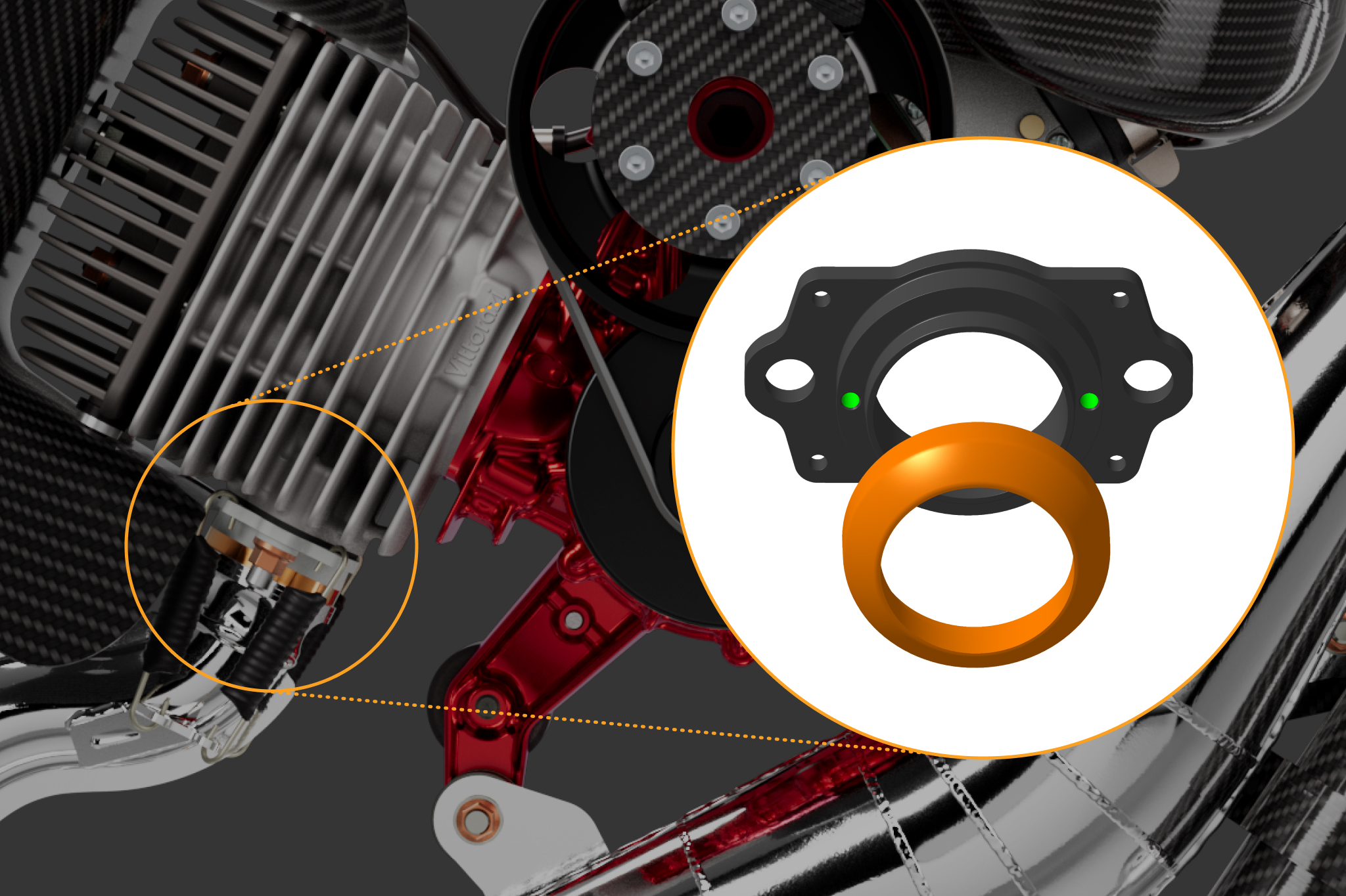

Exhaust manifold flange with extraction holes

The exhaust system of the Moster185 Factory-R MY25 has been improved with the introduction of two extraction holes on the exhaust flange, a modification that simplifies the replacement of the bronze bushing, a crucial component for engine operation. These holes allow easier access, reducing intervention complexity and the risk of damaging the flange during maintenance. Even pilots who prefer self-maintenance will find the process more intuitive without needing advanced tools. Regular and proper bushing replacement ensures smooth and consistent engine operation, while more efficient maintenance means more time to enjoy the flight with peace of mind.

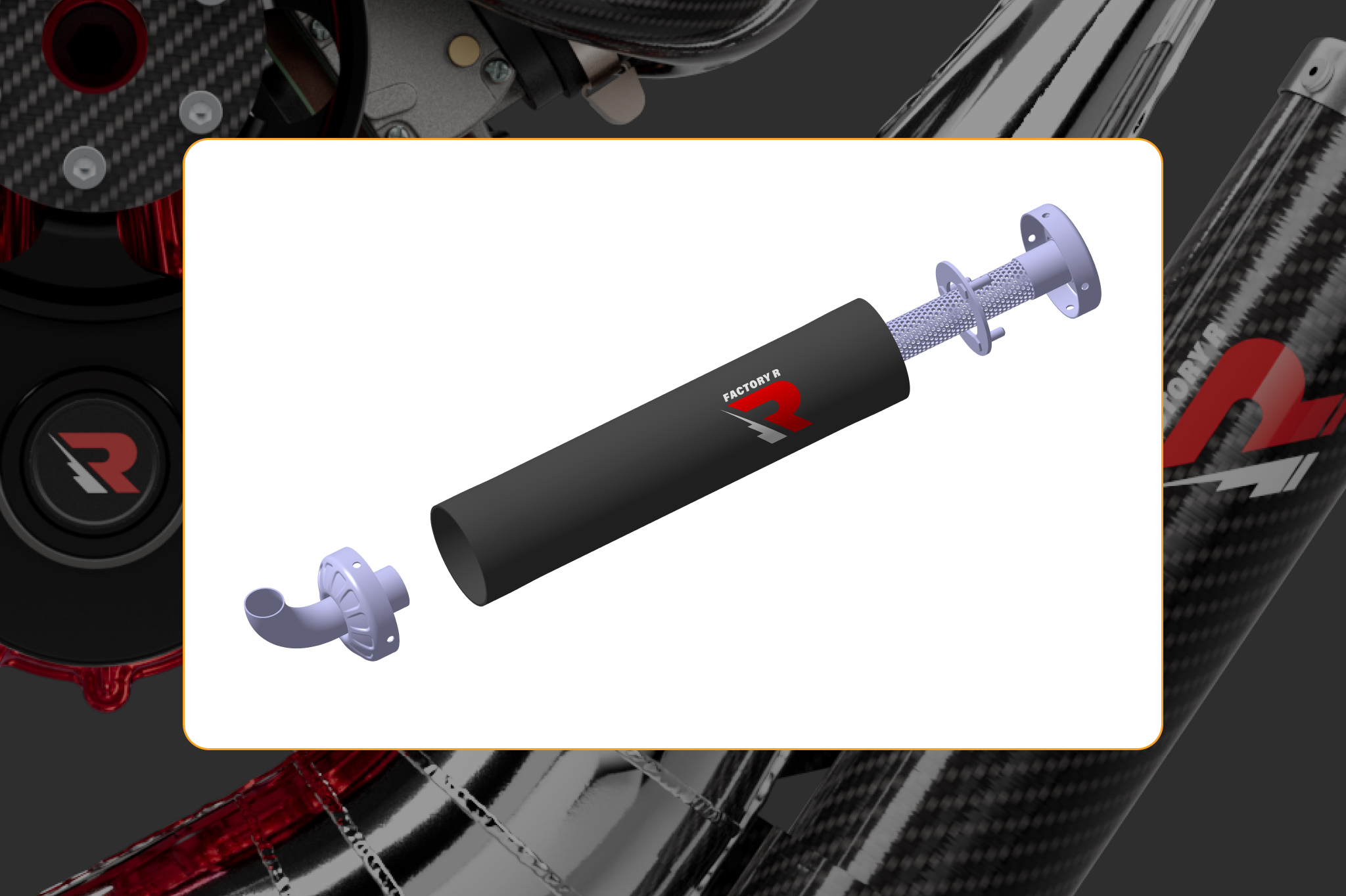

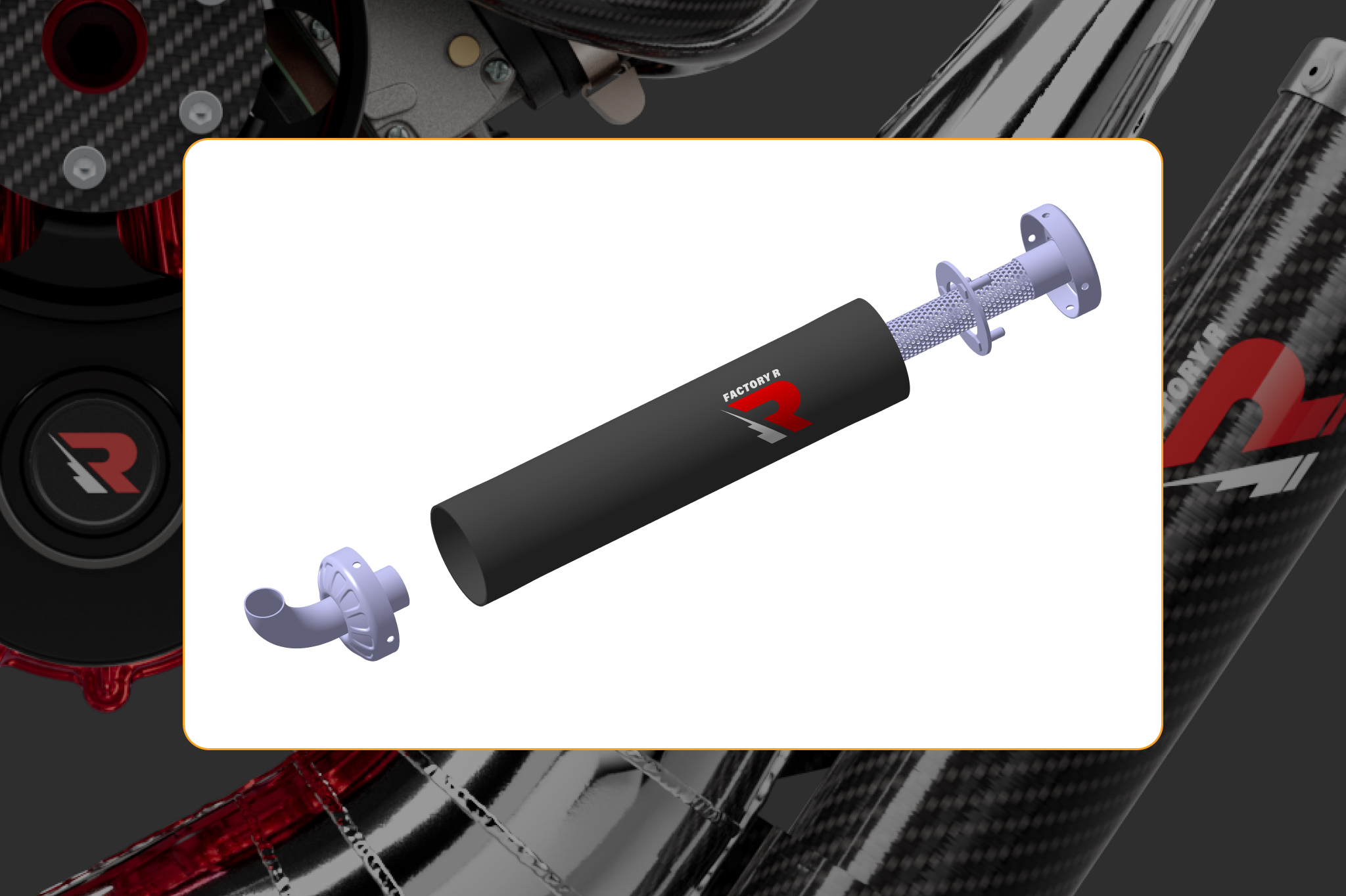

New Silencer

The new silencer of the Moster185 Factory-R MY25 integrates an advanced mounting system that enhances stability during flight and facilitates inspection and maintenance operations. This modification reduces intervention times and ensures a more stable attachment to the muffler, increasing component longevity. The new exhaust tip design, inspired by the racing world, gives it a more captivating aesthetic without altering performance, while replacing the Vittorazi Motors logo with the Moster185 Factory-R logo adds a distinctive touch of elegance and personality.

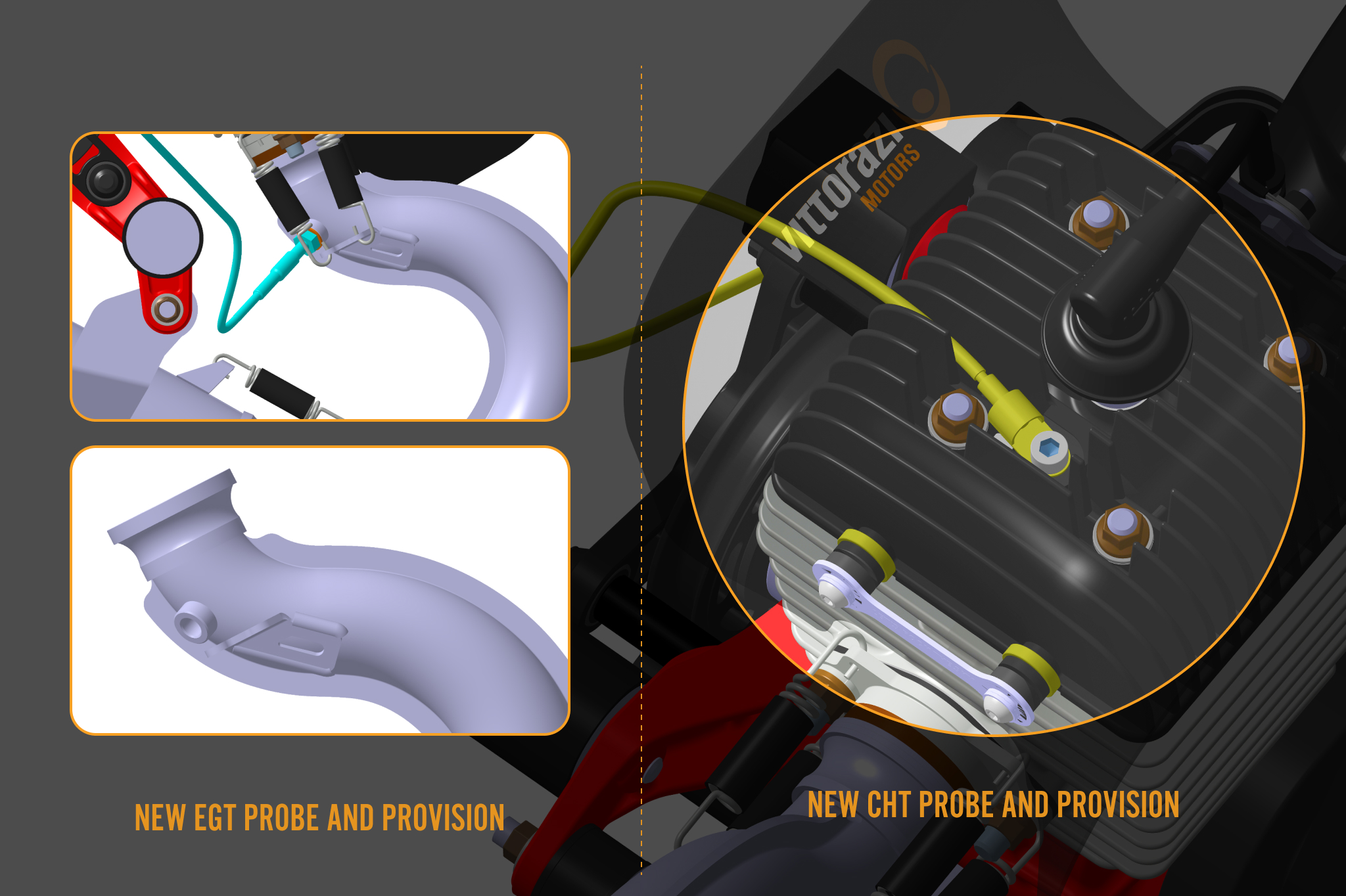

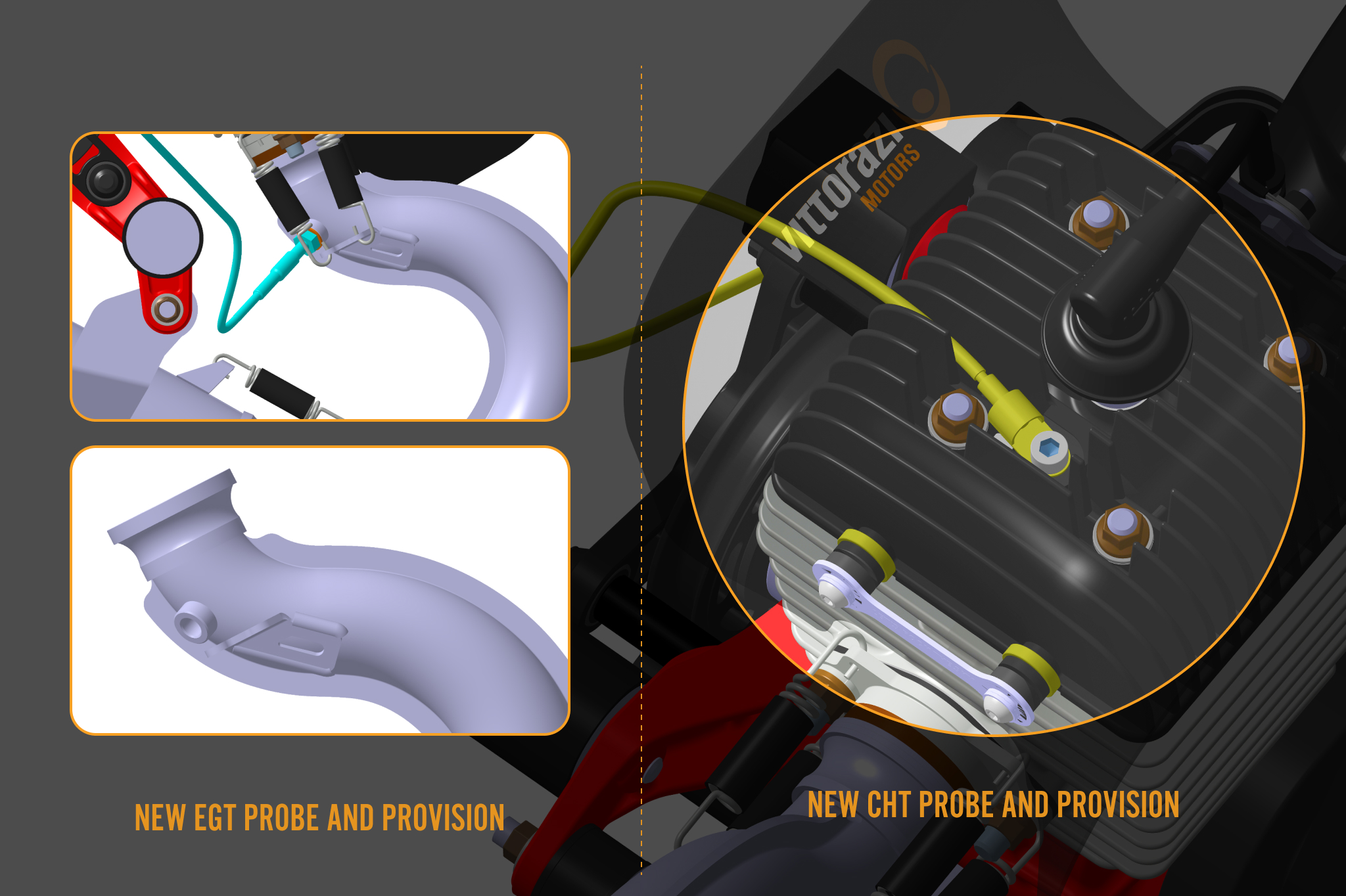

New Vittorazi-designed EGT and CHT probes

The Moster185 Factory-R MY25 integrates two new-generation probes: CHT (Cylinder Head Temperature) and EGT (Exhaust Gas Temperature), already available in EFI technology and now optionally available for the Moster185 Factory-R MY25. Specifically designed to meet Vittorazi Motors’ specifications, these probes provide precise and dynamic data readings and are built to withstand high vibrations and extreme temperatures. Additionally, they feature cutting-edge technical characteristics, including reinforced crimping and a heat-protective sheath.

The EGT probe allows real-time monitoring of exhaust gas temperature, giving pilots advanced control and a deeper understanding of engine behavior. This probe provides highly accurate and dynamic readings, enabling pilots to quickly adapt to operational changes and keep the engine in optimal condition. The integration of this probe, manufactured to industrial-level specifications and using in-house welding processes, minimizes risks associated with improper DIY installations. With this standard setup, the new EGT probe on the Moster185 Factory-R MY25’s manifold ensures greater engine longevity, precise control, reduced wear, and optimized operating conditions.

The Moster185 Factory-R MY25 also features a new positioning and fixing system for the CHT probe. The new strategic housing is designed to avoid stress during spark plug installation and maintenance. This specific placement for the MY25 version introduces new measurement scales and alert limits, ensuring high performance and precise thermal control. Advanced thermal control allows pilots to handle extreme conditions with confidence, ensuring optimal performance and increased engine longevity. Furthermore, the reduced need for corrective interventions guarantees more comfortable and worry-free flights.

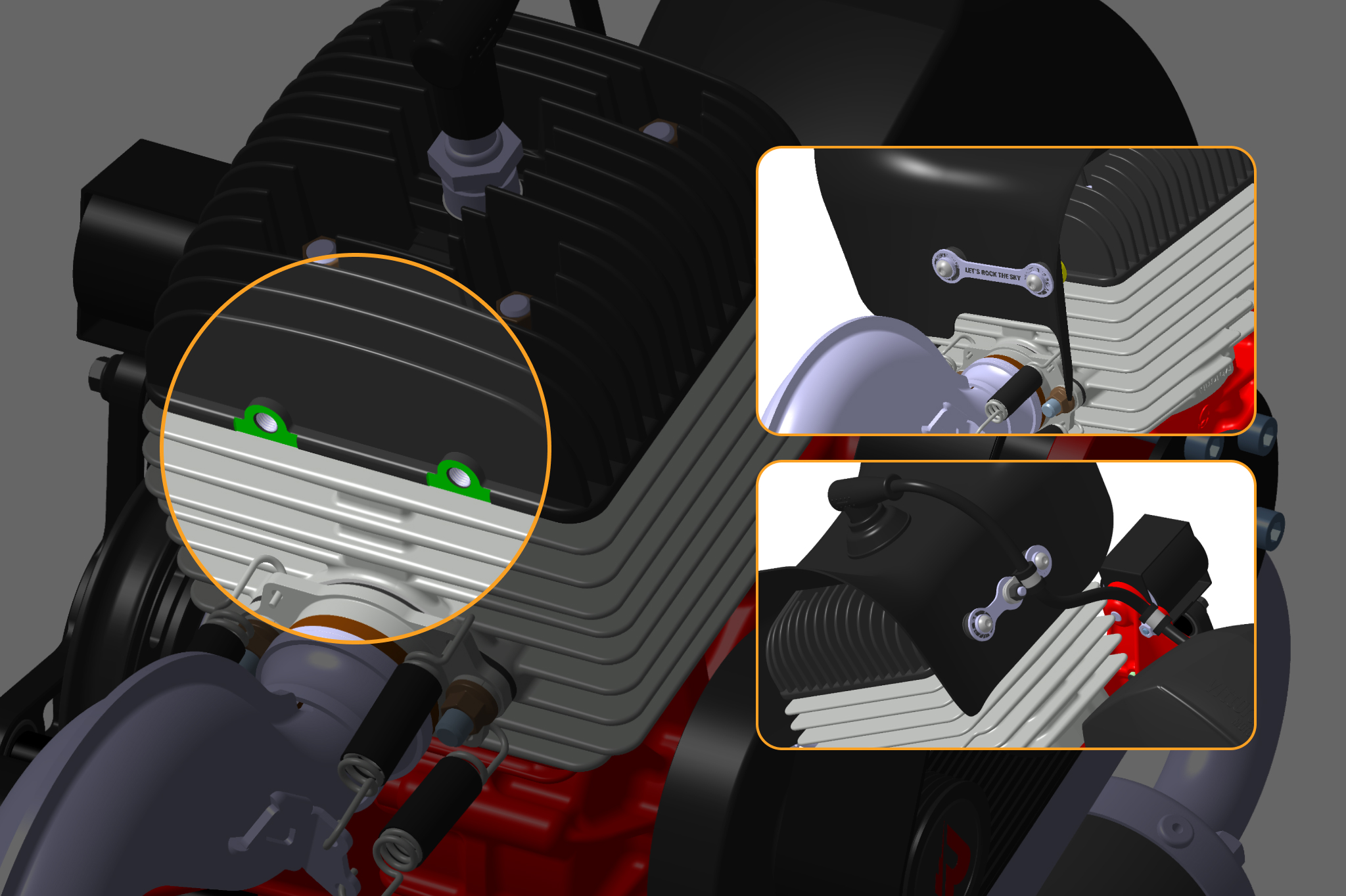

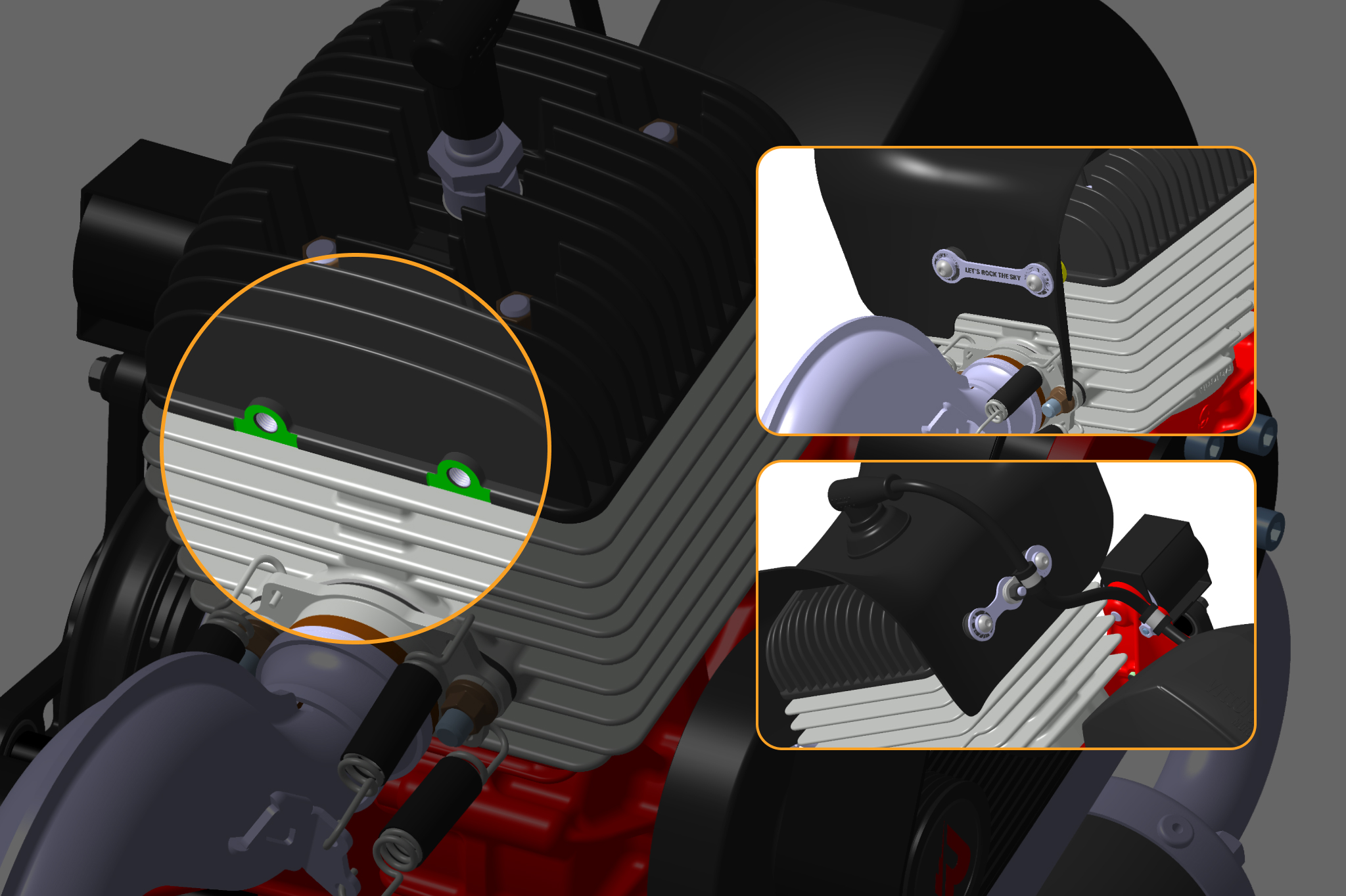

New carbon cooling shroud fastening system

The carbon cooling shroud of the Moster185 Factory-R MY25 features a new mounting system using screws, anti-loosening washers, and spacers for easier installation, along with reinforced anti-vibration mounts. This solution replaces the previous stud-based system, reducing mounting/dismounting times and minimizing the risk of errors during maintenance. The cylinder head has been modified to adapt to the new system, ensuring a solid and reliable connection that enhances overall engine stability. These updates not only simplify the installation and checking of cylinder head nuts but also ensure prolonged durability, optimal performance even in extreme conditions, and a superior-quality system. This innovation has been implemented in the MY25 version by Vittorazi Motors as a result of feedback from our service centers and pilots who have chosen Vittorazi for its quality.

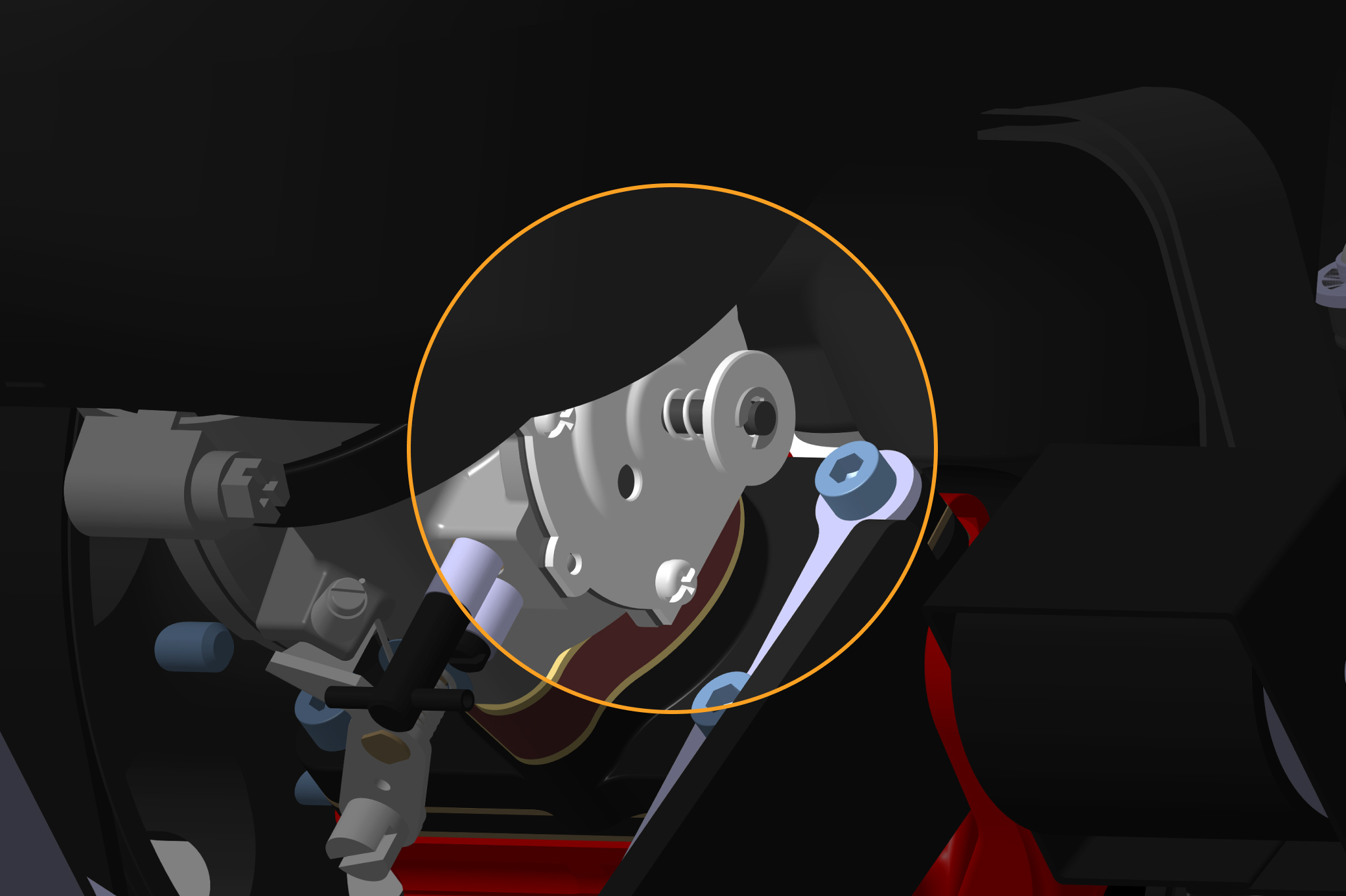

Reinforced primer pin

The carburetor primer pin of the Moster185 Factory-R MY25 has been improved with the use of Ergal 7075 aluminum, an aerospace-grade material treated with anodization for increased resistance to wear and external elements such as exposure to humidity and salt. Additionally, since the primer pin is subjected to constant engine vibrations and potential direct stress from the user during primer activation, the new construction significantly enhances its robustness and durability under all conditions.

Vittorazi Motors is truly “MORE THAN AN ENGINE.” Choosing a Vittorazi engine means choosing much more than just a product. It means becoming part of a major project driven by passionate people, innovation, and a constant commitment to providing unique services in the world of paramotoring. Vittorazi is more than an engine; it is a global distribution and support network to ensure the best possible assistance; it’s a thriving community of paramotor manufacturers, professional partners and flight schools committed to supporting pilots throughout their journey; it is continuous training on cutting-edge technologies; it is a vision that goes beyond flying, one that aims to build trust-based relationships and deliver a lasting promise.

Are you ready to switch to the Moster185 Factory-R MY25? Find your nearest dealer and order now!

Vittorazi engines come with a 2-year or 150-hour warranty.

Dealer Map

Let’s rock the sky!

The new pull-start system of the Moster185 Factory-R MY25 features a self-lubricating bushing positioned between the pulley and pawl housing. This integration improves sliding and reduces mechanical play, ensuring stable and precise operation even in the presence of vibrations and high temperatures. This component extends the system’s lifespan, minimizing wear and overheating. The addition of a retaining screw for the "easy starter" spring, designed to keep the spring securely in place, prevents unwanted movements, while the insertion of a Seeger-Ring ensures smooth and long-lasting movement of the pawl spring. This component acts as a buffer, minimizing friction and stress that would otherwise affect the pawl system. The result is greater durability, smoother operation, a more precise engagement, and optimized safety against potential issues. With the evolution of these components, the Moster185 Factory-R MY25 not only performs well under standard conditions but also withstands extraordinary situations such as poor maintenance, adverse weather conditions, and improper use. A significant improvement for this new MY25 version. This evolutionary step contributes to a pleasant and long-lasting flight experience while offering greater tolerance to actions that may not always align with the maintenance manual, even from less meticulous pilots.

The new pull-start system of the Moster185 Factory-R MY25 features a self-lubricating bushing positioned between the pulley and pawl housing. This integration improves sliding and reduces mechanical play, ensuring stable and precise operation even in the presence of vibrations and high temperatures. This component extends the system’s lifespan, minimizing wear and overheating. The addition of a retaining screw for the "easy starter" spring, designed to keep the spring securely in place, prevents unwanted movements, while the insertion of a Seeger-Ring ensures smooth and long-lasting movement of the pawl spring. This component acts as a buffer, minimizing friction and stress that would otherwise affect the pawl system. The result is greater durability, smoother operation, a more precise engagement, and optimized safety against potential issues. With the evolution of these components, the Moster185 Factory-R MY25 not only performs well under standard conditions but also withstands extraordinary situations such as poor maintenance, adverse weather conditions, and improper use. A significant improvement for this new MY25 version. This evolutionary step contributes to a pleasant and long-lasting flight experience while offering greater tolerance to actions that may not always align with the maintenance manual, even from less meticulous pilots.

The manifold of the new Moster185 Factory-R MY25 has been updated with the addition of a second self-lubricating bronze bushing, which minimizes friction between the manifold and the muffler, allowing smoother movement and reducing the risk of seizing. This update protects the manifold from mechanical stress, prolonging its lifespan and improving system efficiency. In this way, the Moster185 Factory-R MY25 reaches the same level of excellence as the Moster185 EFI improvements.

The manifold of the new Moster185 Factory-R MY25 has been updated with the addition of a second self-lubricating bronze bushing, which minimizes friction between the manifold and the muffler, allowing smoother movement and reducing the risk of seizing. This update protects the manifold from mechanical stress, prolonging its lifespan and improving system efficiency. In this way, the Moster185 Factory-R MY25 reaches the same level of excellence as the Moster185 EFI improvements.

The exhaust system of the Moster185 Factory-R MY25 has been improved with the introduction of two extraction holes on the exhaust flange, a modification that simplifies the replacement of the bronze bushing, a crucial component for engine operation. These holes allow easier access, reducing intervention complexity and the risk of damaging the flange during maintenance. Even pilots who prefer self-maintenance will find the process more intuitive without needing advanced tools. Regular and proper bushing replacement ensures smooth and consistent engine operation, while more efficient maintenance means more time to enjoy the flight with peace of mind.

The exhaust system of the Moster185 Factory-R MY25 has been improved with the introduction of two extraction holes on the exhaust flange, a modification that simplifies the replacement of the bronze bushing, a crucial component for engine operation. These holes allow easier access, reducing intervention complexity and the risk of damaging the flange during maintenance. Even pilots who prefer self-maintenance will find the process more intuitive without needing advanced tools. Regular and proper bushing replacement ensures smooth and consistent engine operation, while more efficient maintenance means more time to enjoy the flight with peace of mind.

The new silencer of the Moster185 Factory-R MY25 integrates an advanced mounting system that enhances stability during flight and facilitates inspection and maintenance operations. This modification reduces intervention times and ensures a more stable attachment to the muffler, increasing component longevity. The new exhaust tip design, inspired by the racing world, gives it a more captivating aesthetic without altering performance, while replacing the Vittorazi Motors logo with the Moster185 Factory-R logo adds a distinctive touch of elegance and personality.

The new silencer of the Moster185 Factory-R MY25 integrates an advanced mounting system that enhances stability during flight and facilitates inspection and maintenance operations. This modification reduces intervention times and ensures a more stable attachment to the muffler, increasing component longevity. The new exhaust tip design, inspired by the racing world, gives it a more captivating aesthetic without altering performance, while replacing the Vittorazi Motors logo with the Moster185 Factory-R logo adds a distinctive touch of elegance and personality.

The carbon cooling shroud of the Moster185 Factory-R MY25 features a new mounting system using screws, anti-loosening washers, and spacers for easier installation, along with reinforced anti-vibration mounts. This solution replaces the previous stud-based system, reducing mounting/dismounting times and minimizing the risk of errors during maintenance. The cylinder head has been modified to adapt to the new system, ensuring a solid and reliable connection that enhances overall engine stability. These updates not only simplify the installation and checking of cylinder head nuts but also ensure prolonged durability, optimal performance even in extreme conditions, and a superior-quality system. This innovation has been implemented in the MY25 version by Vittorazi Motors as a result of feedback from our service centers and pilots who have chosen Vittorazi for its quality.

The carbon cooling shroud of the Moster185 Factory-R MY25 features a new mounting system using screws, anti-loosening washers, and spacers for easier installation, along with reinforced anti-vibration mounts. This solution replaces the previous stud-based system, reducing mounting/dismounting times and minimizing the risk of errors during maintenance. The cylinder head has been modified to adapt to the new system, ensuring a solid and reliable connection that enhances overall engine stability. These updates not only simplify the installation and checking of cylinder head nuts but also ensure prolonged durability, optimal performance even in extreme conditions, and a superior-quality system. This innovation has been implemented in the MY25 version by Vittorazi Motors as a result of feedback from our service centers and pilots who have chosen Vittorazi for its quality.

The carburetor primer pin of the Moster185 Factory-R MY25 has been improved with the use of Ergal 7075 aluminum, an aerospace-grade material treated with anodization for increased resistance to wear and external elements such as exposure to humidity and salt. Additionally, since the primer pin is subjected to constant engine vibrations and potential direct stress from the user during primer activation, the new construction significantly enhances its robustness and durability under all conditions.

Vittorazi Motors is truly “MORE THAN AN ENGINE.” Choosing a Vittorazi engine means choosing much more than just a product. It means becoming part of a major project driven by passionate people, innovation, and a constant commitment to providing unique services in the world of paramotoring. Vittorazi is more than an engine; it is a global distribution and support network to ensure the best possible assistance; it’s a thriving community of paramotor manufacturers, professional partners and flight schools committed to supporting pilots throughout their journey; it is continuous training on cutting-edge technologies; it is a vision that goes beyond flying, one that aims to build trust-based relationships and deliver a lasting promise.

Are you ready to switch to the Moster185 Factory-R MY25? Find your nearest dealer and order now!

Vittorazi engines come with a 2-year or 150-hour warranty.

Dealer Map

Let’s rock the sky!"

["post_title"]=>

string(46) "MOSTER185 FACTORY-R MY25: MORE THAN AN ENGINE."

["post_excerpt"]=>

string(0) ""

["post_status"]=>

string(7) "publish"

["comment_status"]=>

string(6) "closed"

["ping_status"]=>

string(6) "closed"

["post_password"]=>

string(0) ""

["post_name"]=>

string(44) "moster185-factory-r-my25-more-than-an-engine"

["to_ping"]=>

string(0) ""

["pinged"]=>

string(0) ""

["post_modified"]=>

string(19) "2025-02-10 14:30:40"

["post_modified_gmt"]=>

string(19) "2025-02-10 13:30:40"

["post_content_filtered"]=>

string(0) ""

["post_parent"]=>

int(0)

["guid"]=>

string(53) "https://vittorazi.com/?post_type=notizia&p=13412"

["menu_order"]=>

int(46)

["post_type"]=>

string(7) "notizia"

["post_mime_type"]=>

string(0) ""

["comment_count"]=>

string(1) "0"

["filter"]=>

string(3) "raw"

}

The carburetor primer pin of the Moster185 Factory-R MY25 has been improved with the use of Ergal 7075 aluminum, an aerospace-grade material treated with anodization for increased resistance to wear and external elements such as exposure to humidity and salt. Additionally, since the primer pin is subjected to constant engine vibrations and potential direct stress from the user during primer activation, the new construction significantly enhances its robustness and durability under all conditions.

Vittorazi Motors is truly “MORE THAN AN ENGINE.” Choosing a Vittorazi engine means choosing much more than just a product. It means becoming part of a major project driven by passionate people, innovation, and a constant commitment to providing unique services in the world of paramotoring. Vittorazi is more than an engine; it is a global distribution and support network to ensure the best possible assistance; it’s a thriving community of paramotor manufacturers, professional partners and flight schools committed to supporting pilots throughout their journey; it is continuous training on cutting-edge technologies; it is a vision that goes beyond flying, one that aims to build trust-based relationships and deliver a lasting promise.

Are you ready to switch to the Moster185 Factory-R MY25? Find your nearest dealer and order now!

Vittorazi engines come with a 2-year or 150-hour warranty.

Dealer Map

Let’s rock the sky!"

["post_title"]=>

string(46) "MOSTER185 FACTORY-R MY25: MORE THAN AN ENGINE."

["post_excerpt"]=>

string(0) ""

["post_status"]=>

string(7) "publish"

["comment_status"]=>

string(6) "closed"

["ping_status"]=>

string(6) "closed"

["post_password"]=>

string(0) ""

["post_name"]=>

string(44) "moster185-factory-r-my25-more-than-an-engine"

["to_ping"]=>

string(0) ""

["pinged"]=>

string(0) ""

["post_modified"]=>

string(19) "2025-02-10 14:30:40"

["post_modified_gmt"]=>

string(19) "2025-02-10 13:30:40"

["post_content_filtered"]=>

string(0) ""

["post_parent"]=>

int(0)

["guid"]=>

string(53) "https://vittorazi.com/?post_type=notizia&p=13412"

["menu_order"]=>

int(46)

["post_type"]=>

string(7) "notizia"

["post_mime_type"]=>

string(0) ""

["comment_count"]=>

string(1) "0"

["filter"]=>

string(3) "raw"

}