Atom80

THE ENERGY OF FUN

Scroll down

THE ENERGY OF FUN

MY25

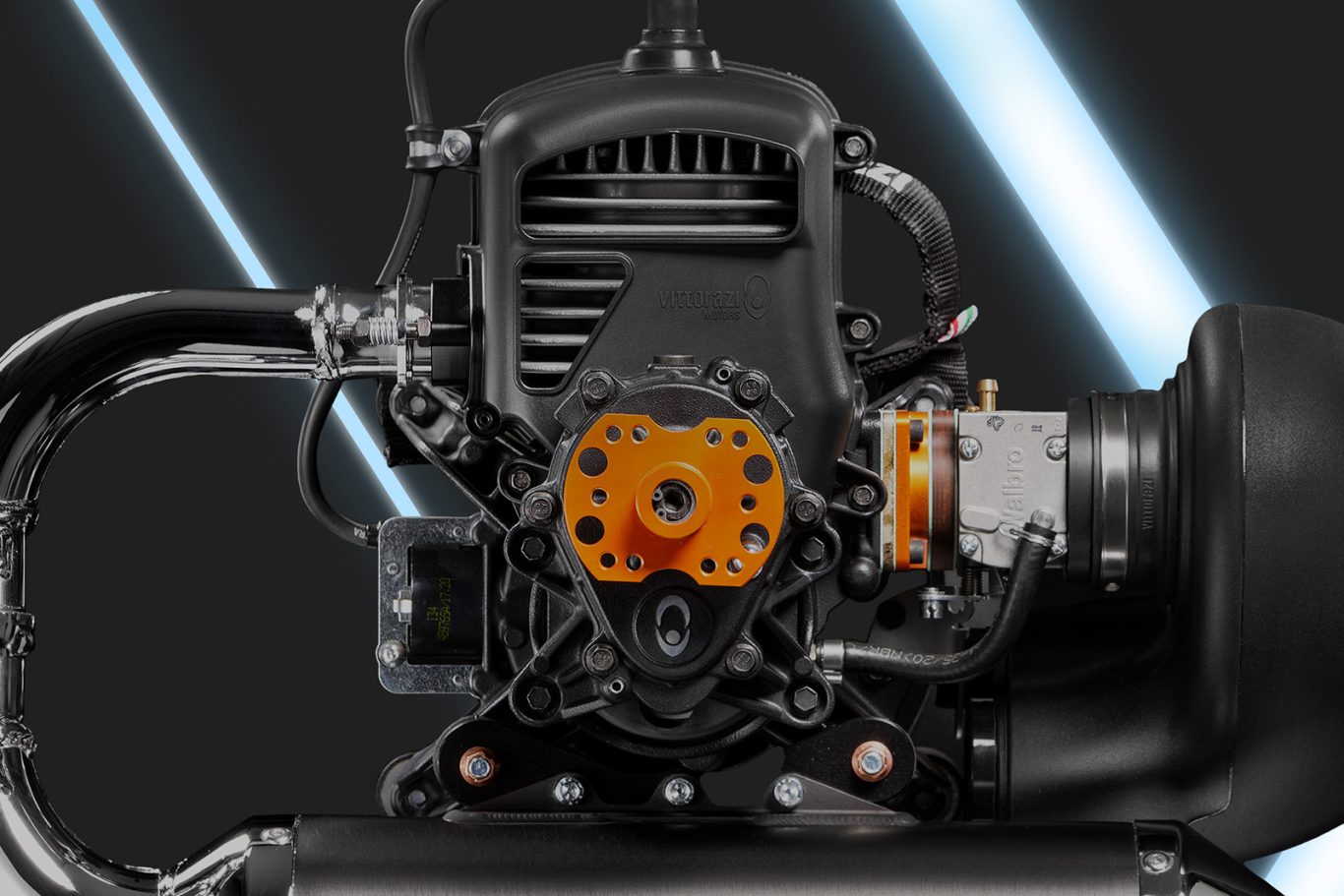

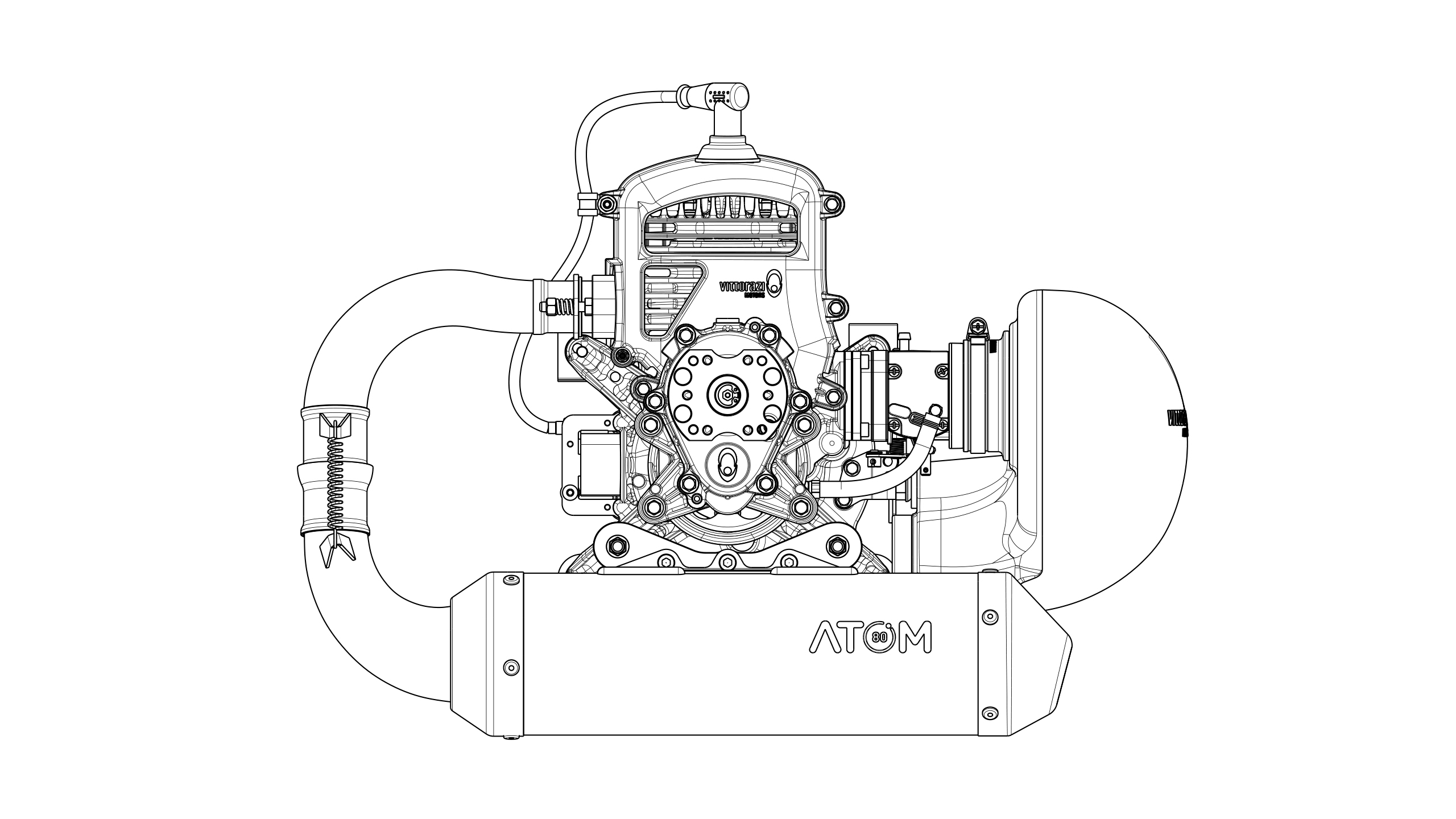

The Atom80 engine embodies lightness and comfort, offering the perfect balance between ease of use and performance. It is ideal for flight schools and newcomers to the world of flying, as well as for experienced pilots seeking a compact and agile engine, and paraglider pilots looking to add the right amount of turbo to their epic adventures. With its excellent range and unparalleled comfort, the Atom80 becomes the perfect companion for long adventures in the skies.

EASY TO CARRY, SIMPLE TO HANDLE.

Lightweight, with a simple structure and optimized for effortless use, the Atom80 allows for stable takeoffs and smooth maneuvers, making it perfect for flight schools, those pilots who like to explore the world from above in total peace of mind, and those who want to transport it easily, even by plane.

Scroll with your finger on the image

for 360° engine rotation

Show more

FOR A COMFORTABLE FLIGHT.

The exhaust system is quiet and efficient, ensuring a comfortable flying experience with minimal noise emissions. It is designed for quick and effective maintenance. Extremely compact, it delivers significant power performance relative to its small displacement. It’s the perfect companion for long adventures in the skies, combining performance and handiness in one exceptional engine.

Cycle

2 strokes

Displacement

78,2 cc

Power

16 HP at 9.500 RPM

Air intake

Airbox silencer - Diaphragm carburettor (WB series) - Reed valve intake

Cooling system

Forced air ventilation system with fan and conveyer

Show more

Combustion

Behind the Atom80 lies meticulous research that has resulted in a highly optimized combustion system. The new cylinder head has been designed with the standard provision for a dedicated CHT (Cylinder Head Temperature) probe. This advanced component, equipped with robust crimping and a heat-protective sheath, is strategically positioned on the new cylinder head to avoid stress during assembly, disassembly, or maintenance of the spark plug. This new location developed specifically for the MY25 version refers to new measurement scales and new alert limits, ensuring high performance and precise thermal control.

Airbox

The intake system of the Atom80 has been designed to maximize power and reduce fuel consumption. The airflow ensures smooth intake, while the carburetor and Lamellar pack have been carefully optimized to lower consumption and deliver consistent performance. The airbox filter, featuring a dual-sponge design, was specifically chosen to provide excellent protection, even in harsh environments such as marine or sandy areas. In the Atom80 MY25, a safety strap for the airbox has been introduced, enhancing robustness, minimizing risks, and providing an additional guarantee of quality for the customer.

Exhaust

The Atom80's exhaust system combines high performance with low noise emissions. The compact design maximizes power in relation to the small displacement, while the chrome surface adds elegance. The new MY25 manifold introduces the standard provision for the EGT ( Exhaust Gas Temperature) probe, made with industrial-grade specifications and “in-house” welding processes. The probe, equipped with robust crimping and heat-protective sheathing, ensures accurate readings and optimal control. This improves engine longevity with control that reduces wear and improves operating conditions.

Transmission

The Atom80 MY25 reduction drive unit offers improved performance through precise alignment of bearing seats and the use of a wave spring, which, by compressing the bearing pack, eliminates axial play and stabilizes the system, reducing vibration for smoother flight. Optimization of gear teeth through an advanced industrial finishing process improves transmission, reducing heat, noise and wear. The result is a more comfortable and immersive flight experience with less vibration, reduced noise, and a more efficient transmission.

Combustion

Behind the Atom80 lies meticulous research that has resulted in a highly optimized combustion system. The new cylinder head has been designed with the standard provision for a dedicated CHT (Cylinder Head Temperature) probe. This advanced component, equipped with robust crimping and a heat-protective sheath, is strategically positioned on the new cylinder head to avoid stress during assembly, disassembly, or maintenance of the spark plug. This new location developed specifically for the MY25 version refers to new measurement scales and new alert limits, ensuring high performance and precise thermal control.

Airbox

The intake system of the Atom80 has been designed to maximize power and reduce fuel consumption. The airflow ensures smooth intake, while the carburetor and Lamellar pack have been carefully optimized to lower consumption and deliver consistent performance. The airbox filter, featuring a dual-sponge design, was specifically chosen to provide excellent protection, even in harsh environments such as marine or sandy areas. In the Atom80 MY25, a safety strap for the airbox has been introduced, enhancing robustness, minimizing risks, and providing an additional guarantee of quality for the customer.

Exhaust

The Atom80's exhaust system combines high performance with low noise emissions. The compact design maximizes power in relation to the small displacement, while the chrome surface adds elegance. The new MY25 manifold introduces the standard provision for the EGT ( Exhaust Gas Temperature) probe, made with industrial-grade specifications and “in-house” welding processes. The probe, equipped with robust crimping and heat-protective sheathing, ensures accurate readings and optimal control. This improves engine longevity with control that reduces wear and improves operating conditions.

Transmission

The Atom80 MY25 reduction drive unit offers improved performance through precise alignment of bearing seats and the use of a wave spring, which, by compressing the bearing pack, eliminates axial play and stabilizes the system, reducing vibration for smoother flight. Optimization of gear teeth through an advanced industrial finishing process improves transmission, reducing heat, noise and wear. The result is a more comfortable and immersive flight experience with less vibration, reduced noise, and a more efficient transmission.

VITTORAZI MOTORS 250CC

(POR Marche FESR 2014-2020 Asse 1 - OS 1 - Azione 1.2)

Il progetto prevede, a partire da risultati di ricerca già acquisiti, l'ingegnerizzazione e l'industrializzazione di un nuovo prodotto..

Il progetto ha tra gli obiettivi: l'ingegnerizzazione e prototipazione esecutiva del nuovo motore, il miglioramento delle caratteristiche prestazionali e tecniche del prodotto, l'industrializzazione del nuovo motore, la promozione del prodotto innovativo e sviluppo della fase di commercializzazione per il nuovo mercato.

Ingegnerizzare, industrializzare e produrre il nuovo motore da proporre a un nuovo settore di clientela, acquisendo una fetta di mercato importante per lo sviluppo dell'impresa.

Investimento totale: 687.291,60 euro | Finanziamento pubblico: 337.675,80